The 11 major rules of running a warehouse:

- Rotate stock so old goods are used first: FIFO (first in, first out). If goods have an expiry date, use FEFO (first expired, first out).

- Stack goods safely.

- Plan the layout of goods for easy access and finding them again.

- Record all movements or losses on the correct forms.

- File all papers immediately.

- Plan ahead: what goods, staff and transport will be required in the next day, week or month?

- Keep goods secure.

- Keep warehouse clean, with daily, weekly and monthly cleaning.

- Dispose of spoiled goods correctly and quickly.

- Communicate objectives, plans, progress and issues effectively.

- Conduct physical inventory on a regular basis.

Definition:

A warehouse is defined as a planned space for the storage and handling of goods and materials. Goods and materials stored in a warehouse are considered as stock, which is also called “inventory”. Warehouses are an integral part of the supply chain, their main purpose being to serve as physical transit points between supply (delivery from suppliers) and demand (end-users or beneficiaries).

Where needed, warehouses allow for the breakdown of bulk deliveries across different requestors or into phased deliveries, and for the combination of loose items into kits to meet beneficiaries’ needs.

A well-managed and well-positioned warehouse allows for speedy responses to both planned and unplanned needs and ensures that both inventory and staff are ready to respond to planned and unplanned needs.

Functions of a warehouse

View and download a detailed diagram of warehouse functions here.

Different types of inventory

It is important to be aware of the difference between stock (inventory), office supplies, office equipment and assets:

| Stock | Office supplies | Equipment | Assets | |

|---|---|---|---|---|

| Definition | Consumable items that are tracked and stored until use or distribution | Temporary or disposable consumables, food or cleaning products required on a day-to-day basis, for use in the office or residence | £1,000 or > 3 years useful life or Powered by electricity or Incurs running costs or Defined as asset by donor | |

| Examples | Programme supplies for direct distribution Office supplies for distribution to beneficiaries, partners Vehicle spare parts, fuel | Stationary Office cleaning materials Food for office consumption | Furniture Housing equipment Household items | Owned property Vehicles Comms equipment IT hardware Large household appliances |

| Reporting requirements | Stock report | None | Property register | Asset register |

| Storage location | Warehouse | In the office | In use or in storeroom* | In use or in storeroom* |

*The storeroom is typically a small room in the office where a small stock of office supplies is kept

Available to download here.

Purposes of holding stock

The main purpose of stock is to de-couple supply and demand in an operation that requires the provision of pre-determined goods and materials.

In an ideal world:

- exact needs are known

- suppliers are reliable

- supply is stable

- infrastructure is stable

- there is little to no need for inventory.

In the humanitarian world:

- needs fluctuate unpredictably

- suppliers are liable to multiple risks (environmental, political, financial)

- supply is often interrupted

- infrastructure is exposed to multiple risks (environmental, political, financial)

- inventory acts as a buffer against structural risks.

Stock ownership

Generally, stock is owned by its original requestor (the person who pays for the goods) and physical management of items and materials is delegated to logistics.

This means that logistics cannot choose to increase or decrease stocks unilaterally and that updates on inventory must be shared between the logistics team and the owners of the stock managed in the delegation.

In that sense, logistics is responsible for the inventory it holds for others, but requestors and programme managers are accountable for the type and quantity of items they require logistics to hold in stock for their use.

Stocks management – roles and responsibilities

RACI matrices are used throughout this manual. They break a process into steps, specifying who is Responsible, Accountable, Consulted and Informed at each step of the process.

| Responsible | Accountable | Consulted | Informed | |

|---|---|---|---|---|

| Warehousing & Stock Management | Warehouse staff | Requestor Budget holder | Programme team Health and safety | Logistics team Finance team |

Available to download here.

The valuation of inventory is critical for the organisation to manage the risk of ownership of stock in general, and in particular to support the definition of insurance requirements.

Financial management of stocks

For financial management of stock in the UK, refer to the Bulwick warehouse SOP, ERU kit SOP, UKO stock management SOP, RLU stock management SOP and the Balance sheet guidance note.

More information on the Regional Logistic Unit (RLU) and Emergency Response Unit (ERU) stocks management can also be found in the RLU stocks and ERUs chapters of the Manual.

The general concepts to bear in mind are:

- Inventory held by international logistics for preparedness purposes is valued in collaboration with the logistics finance business partner, based on procurement information shared by the logistics team.

- The value of inventory held by logistics sits on the British Red Cross balance sheet from the moment stock is received to the moment it is dispatched for use.

- When stock is dispatched for use, the value of the dispatched items is charged to its requestor and taken off the British Red Cross balance sheet.

- When stock needs to be disposed of, logistics must use a write-off form to record the disposal. The value of the disposed items is usually charged to the logistics budget and taken off the British Red Cross balance sheet.

See the Disposing of and writing off stocks and Writing off obsolete assets sections for more details on stock write-offs.

Note: it is recommended that the members of the logistics team who manage stock regularly meet with both their requestors and the finance team to review current stock type, levels and locations, discuss proposed changes (if any), ensure budget management and reconcile stock. In the British Red Cross, the logistics team meet with owners of the stock they manage (ERU kits, RLU representatives) and with their finance business partner on a regular basis.

Stock positioning

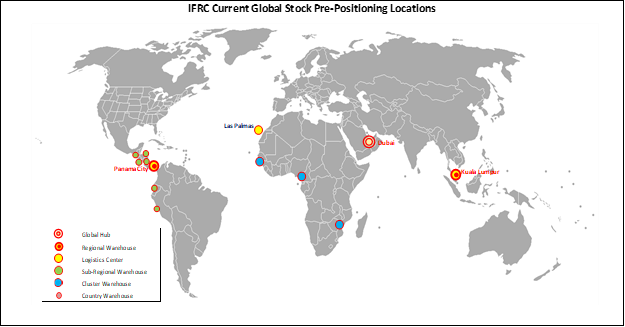

Within the Red Cross Movement, stocks are held at different levels and the processes to follow to access stock vary between levels of storage:

Country level

- This is stock that is available in country.

- Locally available stock can belong to the country’s or to a partner NS and would include the kits that a chooses to hold for -led responses.

- NS that do not hold ERUs may also have stocks available in country, either for ongoing programmes or for preparedness purposes.

Regional level

- This is stock that is held in regional hubs.

- In RLUs (Kuala Lumpur in Asia, Panama City in Americas), stocked by the IFRC and other PNSs and managed by the IFRC.

- In sub-regional warehouses or in decentralised regional stores (“cluster warehouses”), in Harare, Douala and Dakar.

Global level

- This is stock that is held in IFRC-managed global hubs.

- The Dubai and Las Palmas logistics centres are “global hubs”, serving all regions equally.

The IFRC’s global stock strategy aims are:

To cover the initial needs of the immediate aftermath of any disaster, the IFRC, with the stock pre-positioning of their members in the different RLU, has pre-positioned emergency response stockpiles in their network of regional warehouses across the globe, which could support up to 450,000 people at anytime and anywhere.

Read the next section on Building a stock strategy here.

Related resources

Download useful tools and templates

Download the full section here.

Defining the need for goods or services

In the UK

Procuring against UK contracts

View a step-by-step guide of how to procure against UK contracts here.

Procuring in Agresso vs manually (UK procurement only)

View a step-by-step guide on how to procure in Agresso and how to procure manually in the UK here.

The selection of the procurement process will be based on different criteria, such as estimated costs, risks and the lead time available.

Procurement through partners

The financial thresholds detailed here only apply to programmes following British Red Cross or procurement guidelines. Financial thresholds for each will have to be defined and agreed locally, and individual donors can define different thresholds and processes. The GAD determines which guidelines will have to be followed.

View and download the procurement process for UK international here.

Using the Movement’s resources

The British Red Cross has access to established procurement contracts. They are a preferred option when procuring , as they are subjected to strict testing from the ICRC internal QA team and from third-party service providers mandated to verify the quality of the items manufactured by the supplier. Procurement through an ICRC contract must be managed by UK logistics.

Using ICRC contracts for procurement:

View and download a diagram explaining how to use ICRC contracts for procurement here.

British Red Cross can also access IFRC-established contracts. They are particularly useful in the replenishment of pre-positioned stocks, with delivery at the IFRC warehouses (regional logistic units). A global logistics services agreement governs the relationship between the British Red Cross and the IFRC as a procurement service provider. Procurement through an IFRC contract must be managed by British Red Cross UK logistics.

View and download a diagram explaining how to use IFRC contracts for procurement here.

Quote-based procurement

Depending on organisational policies, some purchases will require one or more quotes to be obtained from suppliers (see British Red Cross/IFRC thresholds table).

The requestor will complete and have their requisition form (in British Red Cross UK this is called the ) approved, indicating a desired timeline for delivery, before submitting the form to the designated procurement lead. The procurement lead will consult the market and inform the requestor on a realistic timeline for delivery of the requested items (they can refer to the procurement plan for this).

Depending on the complexity of specifications, an RFQ form or RFQ document should be shared with suppliers for purchases, in order to ensure that all potential bidders receive the same information about the requested goods or services. should be shared with known suppliers and do not need to be advertised or published. They should clearly state the criteria against which the bidders will be evaluated, which must be agreed with the requestor. RFQs can be shared as simple forms to fill out, or as a formal, more detailed document.

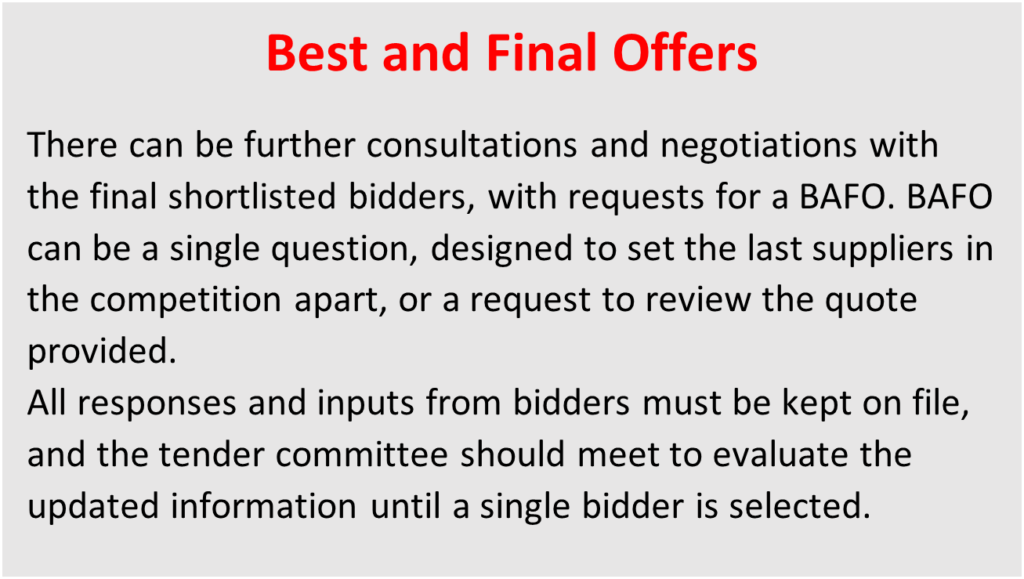

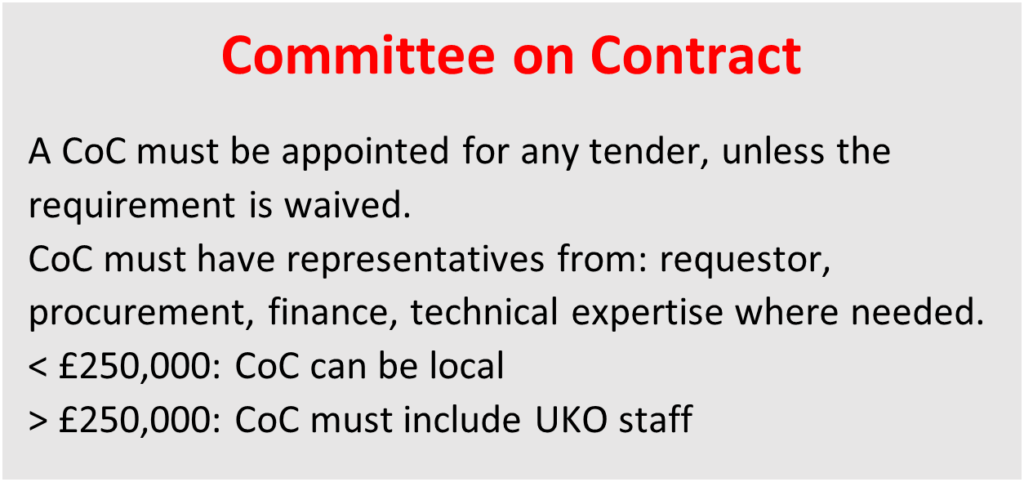

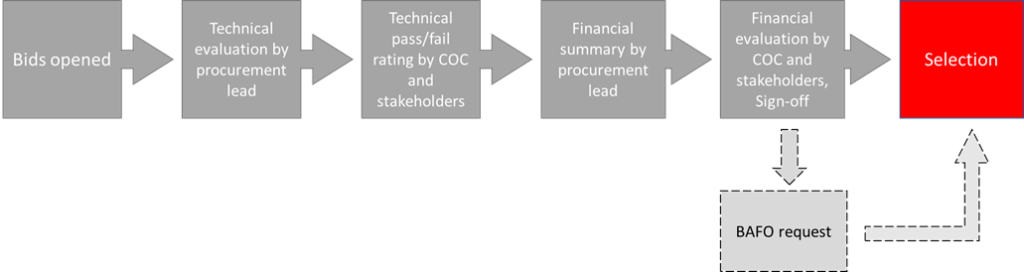

When multiple quotes are received, they are evaluated against each other in a CBA that captures the selection criteria, calculates a weighted score per supplier and gives recommendations as to which is the most suitable supplier. The must be prepared by the procurement lead and submitted to the Committee on Contract (CoC) if one is appointed and otherwise to the logistics team lead, the finance team lead and the budget holder for approval. Where relevant and specified in the original request, technical expertise can be sought (and the technical expert must also sign the CBA).

As part of the analysis, supplier due diligence must be carried out (financial and credit check, sanctions check, counter-terrorism check, ethical policies and standards check, etc.). Note that in the case of and voucher vendors, financial and credit checks can be particularly challenging: pay special attention to the nature of documents required as part of submissions, to avoid failed tenders. For more details on procurement for cash transfer programmes, go to the Procurement to support cash programme delivery section of Procurement of Special Items and Services).

As part of the selection process, it is good practice to request that bidders submit samples of the goods or services they will supply to the procurement lead. Samples should be anonymised by the logistics team and shared with the requestors for their input.

After the quotes’ analysis, a purchase order or contract must be drafted and submitted for approval, together with the complete file (including approved CBA, approved waiver (if applicable) and recommendations).

In , this means raising the purchase order in Agresso and submitting for approval.

View a step-by-step guide of what to do when multiple quotes are needed here.

Tendering for goods or services

Tendering as a British Red Cross partner

As part of the development of a procurement policy, every organisation should define a requisition value above which the market will have to be consulted in more details, via a Request for Proposal (RFP). It is important that the procurement lead works closely together with the requestor to make sure all details are captured in the RFP.

The total requisition value is not the only criterion defining the need for a tender – some levels of risk identified will drive the decision to tender for specific services even below the agree tender threshold (see the Risk Management – Identifying Risks section of Definitions and Concepts).

RFP – details

- Production requirements – to help bidders structure their offer.

- Submission instructions – ways to submit, deadline.

- Terms and conditions of purchase.

- Bidder response document – standard format for all bidders to use to detail their offer.

- Bid evaluation criteria and schedule – include timings and location details for events such as bid opening ceremony.

- Declaration of undertaking – optional addendum procurement guidelines – mandatory if conducting a tender under IFRC rules.

The RFP must be published for a minimum of two calendar weeks for local tenders and three weeks for international tenders. It is usually better to have tenders for cash transfer programming advertised for a minimum of three weeks.

Up to an agreed threshold, it has to be shared with known suppliers only, in a closed tender. Known suppliers can be listed on a database or can be added to the database before sharing the RFP through an Expression of Interest (EOI).

Above that threshold, the RFP will have to be advertised publicly on an online platform or in local newspaper; all interested parties can submit a proposal. In open tenders, reaching out to specific suppliers to signpost them to the public announcement is authorised, to encourage them to bid for the tender.

Restricted tender occurs when only pre-qualified operators can submit offers. Restricted tenders generally start with calls for EOIs, which allows for the advanced selection or shortlisting of suppliers that are then asked to respond to the tender. Restricted tenders are used when the legal framework of procurement is stricter than usual, for example in the procurement of pharmaceutical products, vehicles, or financial services, where suppliers must adhere to certain standards.

- Open tender

– Any bidder can submit an offer against the RFP.

– No pre-vetting of suppliers. - Closed tender

– Only registered supplier must be consulted

– Registration of new suppliers done through EOI before sending out RFP - Restricted tender

– Only pre-qualified suppliers can submit an odder against the RFP.

– Pre-qualification is done through EOI.

– Pre-qualified suppliers are added to a supplier database.

Bids can be submitted physically or electronically (in , they can only be submitted electronically through an e-procurement system, accessed by or international logistics). All bids received must be recorded on a bid opening minutes format, and confirmation of receipt must be sent to each bidder within 24 hours of the deadline stated in the RFP.

Where bids have been submitted electronically but outside of the e-procurement system, they should be sent to a generic email address that only one person can access (British Red Cross international logistics use BRC_International_Logistics@redcross.org.uk).

If bids are received in hard copies (physical copies), it is good practice to use a Bid submission register. After opening the bids, they can be evaluated by:

- a designated group of stakeholders

- a (a minimum of two people, appointed by CPT or by the procurement lead – this is helpful where technical and programmatic considerations need to be considered for the technical evaluation)

- the procurement lead, where no CoC or stakeholder group has been appointed.

Bids must be shortlisted (remove any bids that are obviously unacceptable), scored against the set criteria in a and due diligence, including sanctions and counter-terrorism checks, must be completed (see guidance).

The CBA must be approved by requestor, budget holder, finance approver, logistics approver and where needed by a technical expert, or by the tender committee (or CoC).

The successful bidder must be informed via an award letter that references the tender number, terms and conditions and policies that the supplier must agree to. The award letter should invite the successful supplier for contract negotiations and signature.

View and download a diagram of the process following CBA approval here.

Unsuccessful bidders must be informed through standard letters of regret once the contract with the successful bidder has been confirmed – informing them before then puts the organisation at risk in case the contract cannot eventually be awarded to the successful bidder.

Joint tendering – Tenders can be run in collaboration with other members. This requires significant coordination in the absence of a standard approach. There are ongoing initiatives to coordinate and streamline the process. Contact the logistics coordinators for overseas joint procurement, and the SLM for UK-initiated procurement.

Running a tender from UKO – specifics

Read more about running a tender from here.

Supplier due diligence – counter terrorism and sanctions checks

A carefully designed due diligence framework helps organisations strengthen risk management by establishing healthy partnerships and mitigating criminal, contractual or reputational risks.

Due diligence should rely on a mix of self-certification provided by prospective partners and independent research.

Counter terrorism and sanctions check are part of the supplier due diligence process.

Whenever the international directorate at the British Red Cross or its partners consider engaging with a supplier through a procurement process with a total estimated spend above £5,000 and using British Red Cross funds, the prospective suppliers should be checked using the MK Denial website before being issued a purchase order or contract.

This threshold can be set lower than £5,000 in cases where additional donor requirements apply or in cases where the risks are higher – for example, due to the context or nature of items purchased. The agreed threshold must be proposed as part of the risk register developed as part of the process, agreed with the partner and stated in the . The threshold agreed in the GAD supersedes the standard £5,000 threshold.

If a supplier is issued with multiple with an estimated total value above £5,000, it is recommended that a framework agreement (FWA) is established following a tender process. Where the procurement lead organisation has a framework agreement or long-term agreement (LTA) in place with a supplier, the supplier should be checked periodically, as per the agreed review schedule (this would usually be annual). The supplier due diligence guidance note explains how and when to perform counter-terrorism checks.

Contracting/raising purchase orders

When procuring as a British Red Cross partner

Following the selection process and due diligence checks, or contracts formalise the agreement with the selected supplier.

The following must be included in the purchase orders and contracts:

- original requisition number

- tender reference number

- details of items ordered: standards, quantity, unit price

- added fees, taxes, delivery costs

- payment terms

- for international procurement: applicable incoterm.

The following must be included in contracts:

- delivery schedule and payments

- service level agreement

- all relevant policies attached.

Service level agreement includes provisions for claims and penalties.

It is good practice to include penalty clauses in contracts. Penalty clauses should be linked to the service level agreement and address all points agreed in it: quality, lead times, and all agreed terms and conditions (such as packaging instructions, documentation required, etc.).

| Purchase orders | Contracts | |

|---|---|---|

| Raised by | Procurement | Procurement |

| Consulted | Legal | |

| Approved by* | Budget holder Finance Procurement | Budget holder Finance Legal |

*Seniority of the signatory of the PO or contract is determined by the total procurement value or is the authorised legal representative of the organisation

A set of template contracts is available for download at the end of the section.

- transport contract

- consultancy contract

- rental contract (lease agreements – see template for warehouse lease contract)

- framework agreement

- financial services provider contract template ( template, please adapt and contact British Red Cross international logistics team for support).

Contract amendments:

Contract changes: must be documented, approved by the original approver of the contract, dated and kept on file with the original contract.

Contract extensions: at the expiry date of a contract or when the total value of it has been spent, a contract extension form must be filled out to request an extension. The contract extension form must be signed off by the head of procurement (in BRC, this is the head of or the head of international logistics).

A contract can only be renewed once, and the duration of the extension cannot exceed the duration or value of the original contract. At the expiry date of the extended contract, a full procurement process must be completed again (or waived through a waiver request).

Contracting/raising purchase orders – UK specifics

The requirements in the Contracting/raising purchase orders as a British Red Cross partner section apply, and the must be informed ahead of contracting. British Red Cross corporate procurement tools must be used, i.e. a requisition must be raised in Agresso and approved as per the approval matrix designed in Agresso; once it has been approved, a purchase order or contract can be raised.

Contract amendments for UK contracts: request must be submitted to CPT, who will draft a contract amendment, sign it and share with logistics.

Framework agreements

In general

Ideally based on the ‘80/20 procurement strategy’ so they cover the most procured items or highest spend lines, framework agreements (FWAs) are a specific type of contract that cover several purchases along a determined period.

FWAs should be used to source regularly procured and readily available products where the market prices are sufficiently stable, where the product specifications and prices are fixed for a period of time.

Standard items usually procured under framework agreements include:

- printing material

- office consumables and stationery

- vehicle servicing and repairs

- IT support

- fuel

- travel agency

- generator service

- standard and high-usage – blankets, tarpaulins, jerry cans, cook sets, etc

- Financial services in cash transfer programmes (see the Procurement to support cash programme delivery section of Procurement of Special Items and Services).

A FWA is set up through a tender process (see the Tendering for goods or services section), by circulating a request for proposal (RFP) or expression of interest (EOI) to the open market. The FWA should be reviewed every one to three years.

Selection criteria must be similar to criteria in an RFP but can also include:

- a minimum spend requirement

- minimum order quantity or value requirement

- a maximum spend allowance

- fixed pricing for a standard list of items or fee (for example, travel agency that will apply a fee to each booking)

- turnaround time, from order to delivery service-level agreement.

It is good practice to include penalty clauses in FWAs, just like in other contracts. Penalty clauses should be linked to the service level agreement and address all points agreed in it: quality, lead times, and all agreed terms and conditions (such as packaging instructions, documentation required, etc.).

Once set up with the framework agreement template, a purchase of any value can be made against the FWA, based on the approved price list or following the standard single quote procedure if no price list has been included in the FWA.

FWA set up in the UK for use in the UK

In the UK, the standard awarded by is a two-year contract, with the possibility of a one-year extension (this can change and must be agreed at the start of the project). To set up a FWA, the same steps are followed as for a tender, with the supplier management details added to the specifications. CPT will support by setting up supplier review meetings as needed.

Purchasing

Purchasing is the process of buying items or services without a full procurement process. It can be done in various ways in the British Red Cross.

Purchasing options

From framework agreement (FWA)

- There is no need to complete a procurement process.

- Purchase order can be raised against the FWA directly, per the agreed unit prices or following a quick-quote process.

With a procurement card

- Procurement card can be requested from .

- The card can be used as a credit card for small purchases under £1,000.

- Maximum credit amount is £5,000.

With a Caxton card

- Caxton card can be requested from SSC.

- For use for personal expenses while travelling.

- Not for operational expenditure unless on an deployment.

Online purchasing

- Out-of-pocket up to £1,000.

- > £1,000: must be managed by procurement lead.

Petty cash

- Out-of-pocket or with professional cash advance up to £1,000.

- Claim expenses/reconcile advance against receipts.

Read the next section on Managing procurement here.

Related resources

Download useful tools and templates

- Request for quotations (RFQ) form

- RFQ document

- Comparative Bid Analysis (CBA)

- Committee on contract terms of reference

- Request for proposal (RFP)

- Bid opening minutes

- Bid submission register

- Supplier due diligence guidance

- Award letter

- Letter of regret

- Risk register

- GAD

- Contract extension form

- Framework agreement (FWA) template