The Emergency Response Unit (ERU) kit is designed to support emergency teams deploying in the field and make them as self-sufficient as possible. The kits that are put together and maintained by National Societies contain key items for the ERU teams to perform their role, including infrastructure items to help operate offices and warehouses such as tents and generators, as well as items for delegates themselves, such as camping and kitchen equipment.

The purpose of the kit is also to act as a capacity-building tool – there is a general rule that items sent into the operation will be left with the , for use in future disasters. Once the kit has been dispatched, the British Red Cross’ international logistics team will generally procure a new kit. When a team wishes to return specific items of a kit, they will propose it to the logistics and emergencies teams, who will make a decision.

The British Red Cross holds two types of ERUs:

- logistics (the British Red Cross holds two full kits, so can potentially deploy two Logistics ERUs at the same time)

- mass sanitation module for 20,000 people (MSM20).

As this is an standard tool, the kit list is standardised across ERUs – the lists can be found on the IFRC standard product catalogue (SPC). National Societies can add items to the kit, but they cannot take any away.

The National Societies that hold the ERUs meet regularly in Geneva and sometimes review and update the kit list, but this can only be done in agreement with the other ERU holders.

For more details about the procedures that apply to the maintenance, replenishment and deployment of the ERU kits that the British Red Cross holds in stock, refer to the IFRC website, the ERU kit SOP and the ERU chapter of this manual.

Read the next section on RLU stock management here.

Related resources

Download useful tools and templates

Download the full section here.

Once the warehouse is selected, sourced, set up and the team has been put together, the warehouse operations can begin.

Warehouse access

All staff members with access to the warehouse (keyholders) must be recorded.

A keyholder list must always be kept and updated: anyone gaining access to the warehouse must sign the key sign-in and -out list (kept in hard copy in the warehouse or logistics office). The warehouse manager is responsible for keeping the list up to date, and the logistics delegate is accountable for ensuring the list is always up to date and available and should therefore review the list periodically.

Warehouse maintenance

Regular inspections must be scheduled.

| Clean | Check | |

|---|---|---|

| Daily | Floors | Pest signs Locks |

| Weekly | Walls Sides of racks, shelves, fridges | In-depth check for pest Stability of racks, shelves |

| Monthly | Complete deep-clean: floor, storage, structure, roof, gutter, surroundings | Wall cracks Water leakages |

Available to download here.

A maintenance schedule must be put together and shared, detailing all types of scheduled maintenance and status (equipment, building, facilities etc.). All maintenance undertaken and the matching findings must be recorded and signed off by the warehouse manager.

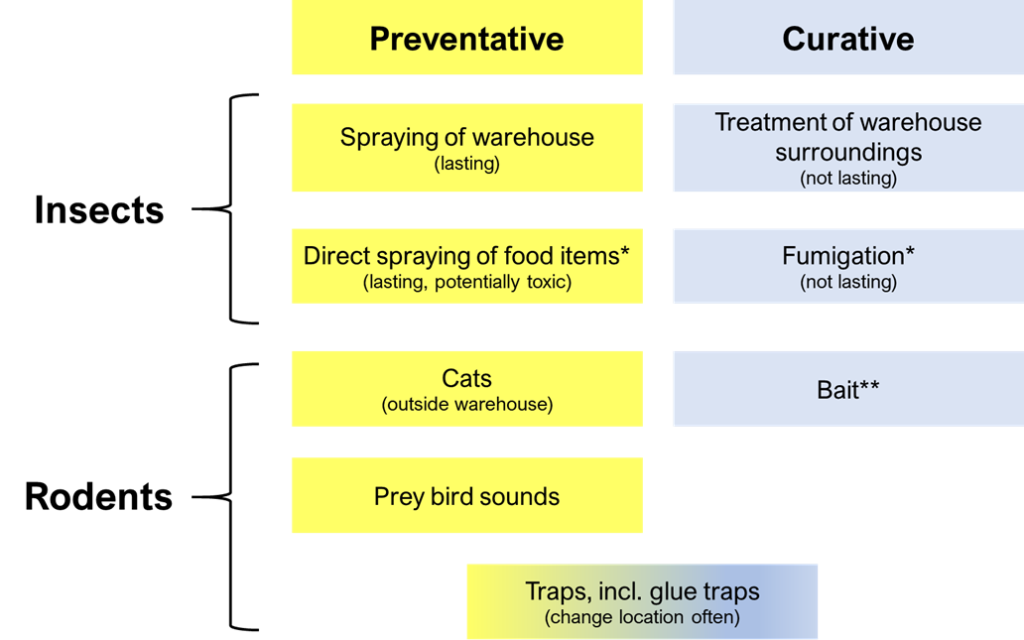

Pest control

Pests are a major risk for warehouses and can critically damage items in stock.

The most common forms of pest found in storage spaces are:

- Rodents (rats and mice) – destroy packaging and consume foodstuffs and medicines, also contaminate them.

Eliminating places in and around the warehouse where rodents can breed is the most effective way to prevent an infestation. Traps, with or without poison, can also be used. - Spiders

- Beetles

- Other insects: termites attack stock and wooden structures; cockroaches and moths attack grain and flour.

Harbouring pests in the warehouse can jeopardise the integrity of the items in stock as well as damage personnel health. If left unattended, an infestation can result in extensive property and product damage and can even affect the warehouse’s structural integrity.

As a preventive measure, warehouses and stored items should be carefully inspected on a regular basis for signs of infestation (a quick daily check, an in-depth weekly check, an extensive monthly check). Using soapy water or a mixture of water and vinegar (1:1 ratio) for the deep cleans is the best preventive measure against pests.

Incoming and outgoing stock should be inspected as they are loaded or unloaded. Random samples should be taken from newly arrived consignments to ensure the quality of the goods and to prevent infested goods entering the warehouse and contaminating other stock. Alternatively, certificates must be obtained from the manufacturer and transporter to guarantee that the items delivered are free of pests.

View a detailed pest inspection checklist here.

What to do in case of infestation

If infested stock is found, immediately separate and quarantine them from the rest. Consult with local experts in the Red Cross Red Crescent, World Food Programme, Food and Agriculture Organization, government or university agriculture departments and/or commercial fumigators.

The warehouse manager must promptly report all infestations to the Logistics delegate and/or the logistics coordinator in .

The choice of the optimum pest-control product, dosage and method of application should be left to an expert. Using the wrong product, method or dosage could render the treatment useless or the goods hazardous to human consumption. Only trained pest removal experts should be allowed to decide on the treatment method.

*Items may need to be procured internationally – refer to your logistics coordinator.

**Be mindful of local food practices. Rats poisoned in the warehouse may escape and be eaten by local population.

Humidity control

A lot of the items typically stored in humanitarian supply chains (grain, flour, cans of food, drugs, machinery, kits or construction materials) are sensitive to extreme humidity, and a lot of the places where humanitarian supply chains operate have humid climates.

Humidity levels must therefore be tightly controlled in an -operated warehouse to maintain the quality of the items in stock and avoid losses. It is recommended that hygrometers be fitted in the warehouse and that humidity levels be checked and recorded every day, especially during rainy seasons. Where humidity levels are high, consult with your regional logistics coordinator or technical advisor to agree workable mitigating measures.

Temperature control

All warehouses must be equipped with temperature-recording devices. Ideally, several of them must be placed throughout the warehouse, close to the ground and to the ceiling, and at both ends of the warehouse.

The readings of the temperature trackers should be extracted each month by the warehouse manager, or manual temperature recording forms should be maintained and filed.

Temperature requirements are usually printed on the items’ packaging or available from manufacturers/suppliers directly.

Chilled and frozen goods require special refrigeration equipment and should be handled with care.

Examples of temperature-sensitive goods include medicines and foodstuffs. These goods must be kept within a certain temperature range from the time of their manufacture to the point of their consumption. As an example, many vaccines need to be kept at between zero and eight degrees Celsius. If temperature limits are not respected, vaccines will often lose their efficacy or original expiry dates will no longer be guaranteed. Where cold chain failures occur, details of actions to take to guarantee the safety of the exposed items can be sought from suppliers or manufacturers. Products might become unusable and require disposal and/or destruction.

A supply chain that deals with such temperature-sensitive goods is known as a cold chain. In a cold chain, measurements are taken, and checks are made to confirm that the goods have remained within the specified temperature range throughout the chain. Cold chain failures are a frequent cause of problems in immunisation programmes and other medical programmes.

From a warehouse perspective, the vulnerable parts of the cold chain are:

Unloading and loading operations: often these involve moving goods from one area to another, which poses a challenge to ensure products stay within their allowed temperature range.

Interrupted power supply: to support an active supply chain, constant power is needed. The use of stabilisers and battery switch is highly recommended where an active supply chain must be maintained.

In warehouses where temperature-sensitive items are stored, there must be a clear temperature control procedure with a process in place to ensure temperature are checked and recorded twice per day. All cold chain materials must be checked twice daily – use the temperature recording forms to track temperature in fridges and freezers. One form should be available for each of the fridges in use.

Standard storage temperatures are normally defined as follows:

- deep freeze: below -15ºC

- refrigerator: +2ºC to +8ºC

- cooled: +8ºC to +15ºC

- room temperature: +15ºC to +25ºC.

To learn more about cold chain management, check out the Logistics Cluster guidance document.

Good storage practices, by item

Food

Detailed information on how to store food can be found here.

Medical supplies

Detailed information on how to store medical supplies can be found here.

NFIs

Detailed information on how to store NFI (non-food items) can be found here.

Construction materials

Detailed information on how to store construction materials can be found here.

Dangerous goods

Detailed information on how to store dangerous goods can be found here.

Chemicals

Detailed information on how to store chemical products can be found here.

Kits

Detailed information on how to store kits can be found here.

Insurance

You should ensure that your stock and warehouse are covered by insurance.

The stock held in UK ( and Bulwick sites) is covered under the British Red Cross insurance policy. The current policy covers the value of stock held at both locations and approximations of the stock’s value are shared with the insurance manager.

The excess for insurance of stock in the UK is £5,000 – any losses or damages under this value are not covered and cannot be claimed through the policy. Replacement for these items must come out of the logistics team budget and be discussed with finance.

For losses or damages over £5,000, the UK insurance manager must be contacted to process the claim. If the level of damage is over £10,000, the insurance company may send an inspector to validate the damage. Reach out to the Logistics team for more details on the insurance procedure.

Once the claim has been processed, the money will be returned to the insurance manager, who will re-code this to the logistics budget. The items’ value should remain on the balance sheet until the money from the insurance claim has been transferred to the balance sheet (see the Financial management of stocks section of Definitions and concepts). Finance will inform logistics when the insurance refund is captured in their account.

For overseas projects, refer to the partner insurance policy and make sure stock is covered against theft, flooding, fire, destruction. The warehouse lease contract may also state whether insurance should be purchased by the lessor or the lessee.

Receiving stock

Plan for reception

Request details of incoming goods as early as possible, with the estimated weights and dimensions clearly stated on the documents.

Arrange your reception area to ensure that the full consignment can be temporarily stored before being moved into the bulk storage area – if necessary, make temporary adjustments to the warehouse layout (reduce the dispatching area surface, for example) to accommodate the consignment. Make sure any temporary changes to the layout are communicated to the warehouse team.

If receiving a cold chain consignment, make sure you have a spare fridge in the reception area. If necessary, prepare passive cold chain (isotherm carton boxes or cool boxes fitted with ice-blocks) to use as extra reception area.

When receiving large consignments, it is good practice to draft a reception plan with end users to capture their priorities. The reception plan should detail:

- the extra capacity needed for offload/check/storage of the incoming goods

- the re-scheduling of all major consignment preparations to focus on quick reception

- the order of priority in which items should be checked and placed in the bulk storage area (i.e. available for dispatch).

Where possible, an offloading plan should be made available for the offloading process: have a list of all the boxes for each or order (see the Receiving international stocks from IFRC section below), so that offloading supervisors can tick the boxes one by one as they are offloaded.

Upon reception of the consignment

Check that all documents are attached to the consignment:

- commercial invoice

- gift certificate

- packing list

- waybill, bill of lading, air waybill or sheet

- relevant customs clearance certificate (tax waiver documents, for example).

If receiving containers, ensure that the container seals are in good condition (take pictures if possible).

Proceed to offloading (use the offloading plan, if available), checking the condition of each box or pallet as it is offloaded and checking the labels on each packaging unit.

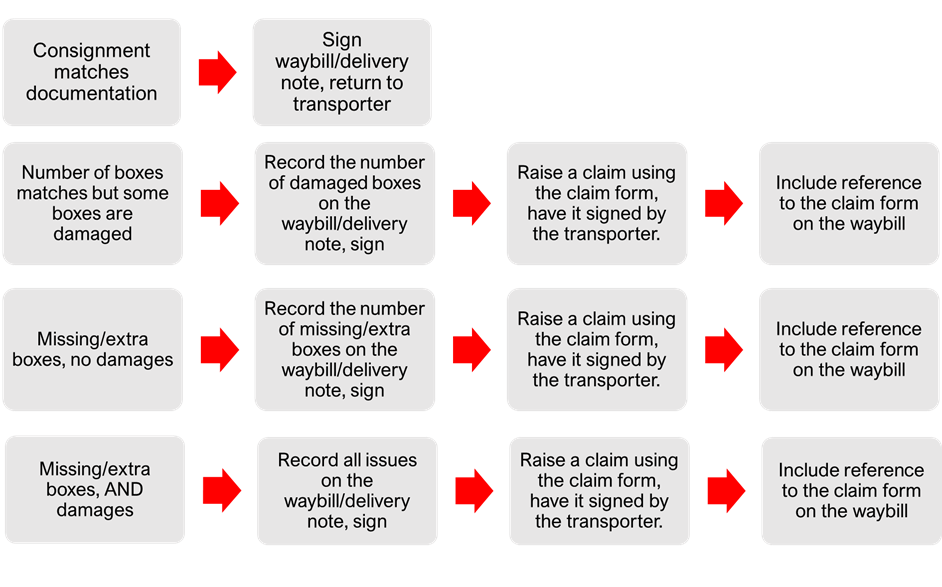

Confirm that the number of boxes offloaded matches the consignment documentation (purchase order and packing list in particular). If they match and no damaged boxes are found, sign the waybill/delivery note provided by the transporter.

Available to download here.

If receiving a cold chain consignment, read the temperature-monitoring devices attached to the consignment to confirm cold chain has been maintained throughout the transport process. Where an anomaly appears on the readings, record it on a claim form and have it signed by the transporter. Include reference to the claim form on the waybill and share the claim form and temperature readings with the delegation’s pharmacists or medical staff to confirm that drugs are fit for use.

Check and inspect the contents of each box to confirm the exact quantities received against the packing list attached to the consignment. Record any discrepancy and reconcile once all boxes have been inspected (sometimes all ordered goods are in the consignment, but the packing lists does not match the physical packaging).

For more details on documenting procedure for the reception and despatch of goods, refer to the Transport chapter.

Document the reception

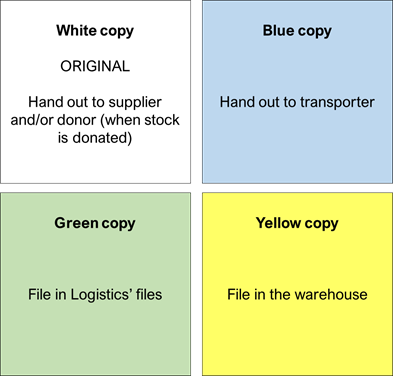

Raise a GRN to confirm the exact quantities received. The must be raised in one original and three copies.

When the GRN is raised electronically, it is good practice to inform all stakeholders and keep soft copies on file or in archives.

Raise a claim in case there are any discrepancies against the shipping documents, in quantities or in quality (see the Upon reception of the consignment section above.)

Record all incoming quantities on the appropriate stock cards, referring to the GRN number.

Record all incoming quantities on the stock cards, referring to the GRN number.

Make sure the stock levels are updated as per the applicable stock tracking method:

- If using an electronic system, stock levels should be updated automatically when posting a GRN.

- If manually updating the stock levels, make sure the updates are captured on the stock cards and in the upcoming reporting cycle.

Keep a copy of the signed waybill on file, including copies of any claims raised and enter them on a claim tracker for follow-up. Provide a copy of the waybill and GRN to the procurement lead to add to the procurement file.

Some consignments will require inspection by a third party (this would have been agreed at the time the order was placed). In this case, a company must be selected to observe the reception process, sample the items received as per the agreed sampling method and take the samples away for analysis. Typically, items that require third-party inspection would not be available for distribution until the inspection results are available. Samples taken for inspection should be recorded as sampled quantities – this quantity should be withdrawn from the GRN and should not be included in the quantities recorded in stock.

Receiving stock for the British Red Cross (in UK or at )

With Agresso

Where items are received into stock through an Agresso purchase, the physical GRN must be raised in the usual way and received quantities must be updated in Agresso. To do so, the receiver must open the Agresso and enter the received quantities in the “quantity received” column. Where deliveries are incomplete, the Agresso PO should be closed after the received quantities are consigned against the PO quantities.

This applies to all stock purchased through Agresso, including pre-positioned stocks (see the RLU stocks management section for more details on RLU stocks).

Receiving international stocks from IFRC (pipeline report and )

The pipeline report

The pipeline report indicates the type and quantity of goods in the pipeline for internationally sourced supplies for a given operation, as well as their point of origin and expected/actual date of arrival.

The pipeline report allows logistics delegates in the field to pre-arrange warehouse space, custom clearances and transport. Depending on space availability and need, goods may be taken from border posts and airport and port facilities to a central warehouse or directly to distribution-point warehouses. The pipeline report indicates all the consignments (i.e., past, ongoing and future shipments) and CTN allocated to that operation.

Regular updates of the pipeline report should be shared with the ’s regional logistics unit leading the operation, National Society staff, donors, operational partners and whomever else the logistics coordinator deems relevant to the success of the operation.

The pipeline report serves various functions:

- Distribution managers can use it to pre-plan distributions according to incoming items from donors and international procurements.

- Other operational agencies, as well as customs clearance agencies, can be in copy of the pipeline report.

They can assist in establishing a global overview of relief items for the operation and to facilitate inter-agency coordination and the preparation of reception/clearing plans.

View and download a pipeline report here.

The regional logistics unit (RLU) has ultimate responsibility for updating all aspects of the pipeline report – both headquarters’ information (new donor commitments, consignment departures, etc) and field-based information (arrivals, losses, etc). The RLU shares all relevant pipeline information with the field daily, and even more frequently at the beginning of an operation.

Pipeline reports are automatically generated by the mobilisation software programme. The RLU is responsible for all data entry into the software programme, hence, for updating the pipeline report. The field-based logistics delegate is responsible for confirming and reporting to the RLU on the state of all consignments immediately following their arrival. The delegate must also share a copy of the to the RLU so that it can be sent to the appropriate donors and/or suppliers.

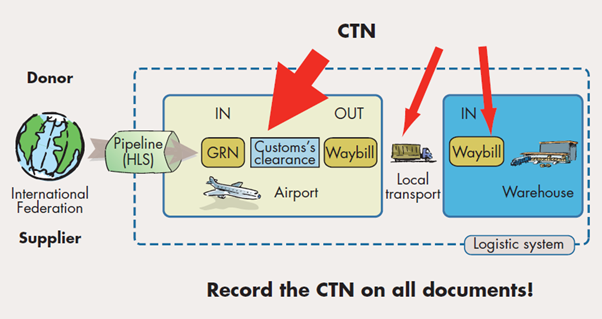

The CTN – Commodity Tracking Numbers

- Each shipment is assigned a unique consignment tracking number by the IFRC’s logistics department, called CTN.

- A consignment refers to a shipment that is handled by a common carrier. This shipment may contain only one type of goods or a combination, each with their own CTN.

- Large donations with the same CTN may need to be sent in several shipments and will thus have multiple consignment numbers.

- The consignment number and the CTN are key elements in the tracking process – they must both be recorded on the GRN so it can be matched to the goods in the pipeline report and a report sent to the appropriate donor.

- Unsolicited goods donations will also appear on the pipeline report, however they will not be allocated a CTN.

The CTN is assigned to each donated or procured commodity. It is also the primary tracking information used to identify the source (donor) of the goods for accurate reporting and must appear on all documents. Shipping, clearing and forwarding documents should be filed by CTN reference for ease of traceability.

The RLU allocates a CTN at the time of donation or procurement. Prior to procurement of any relief item (such as non-food, food, water and sanitation or health supplies) for delivery in the field, a CTN must be requested from the RLU.

It is extremely important to mark this tracking number on each document and, where possible, on each package. The RLU must be contacted in case of missing CTN or, in the unlikely event that none was pre-assigned, to acquire one.

The CTN is not the item code. An item code is the number assigned to each item listed in the standard product catalogue which is published by the IFRC (available online). The item code allows easy reference of items in the catalogue, which describes the standard specifications of individual relief items.

Dispatching stocks

See the Planning, tracking and reporting on transport section of the Transport chapter.

Relocating stocks to a new warehouse

Some programmatic or contextual changes (insecurity, lease conditions, etc) may require moving stocks to a new facility. This is a resource-intensive process and should be planned well in advance, to ensure that the programme’s staff (including support functions) are aware of the timings, implications and resource requirements involved.

Transporting the entirety of an operation’s stock requires careful planning. If the exact weight and volume of the stock is known, it will be relatively easy to calculate truck requirements for the move. If such data is not available, the most practical way to prepare for the move is to mark areas on the floor of the warehouse, their dimensions corresponding to the trucks available for the move, and transfer the stock into these markings, stacking it to the maximum height of the truck, while incrementally dismantling the storage units, and recording all items moved into each of the marked out areas.

Ensure that all items in the warehouse are included in the volume calculations. This includes stock, storage systems, office materials, equipment and machinery, spare materials, generators, etc.

Cold chain stocks must be transferred to passive cold chain containers (cool boxes with ice packs) for the duration of the move. It is preferable to use air transportation for cold chain items if the move is long-distance (more than 12 hours by road).

Documenting the contents of each truck (packing lists and waybills) and scheduling the trucks’ trips to the new warehouse is essential.

Ensure that the stocks needed for distribution most urgently are moved into the new warehouse first and pace the arrivals of the trucks to leave time to place each shipment into storage before the next one arrives.

Ensure that restricted goods are transported in locked containers as far as possible, that dangerous goods are transported separately and that quarantined stock, if it must be transported, is transported separately.

Note: where stocks are being moved to a distant location, ensure that the trucks used (whether hired or owned) can stay overnight at secure locations and have all the necessary road permits to enable them to transit without delays or obstacles.

The rules and guidance points listed in the Good storage practices section above apply to storage in transit.

Relocating to a temporary warehouse

Rubb Hall

The Rubb Hall takes about two days and a team of 12 people to dismantle (and the same to re-erect it in its new location). Ensure that you follow the instructions closely when dismantling the tent. This means that the transfers need to be well-scheduled, taking into consideration the dismantling time, the transit time and the re-erecting time.

The items stored in the Rubb Hall will likely have to be temporarily stored in a different facility (probably another Rubb Hall erected nearby) for at least a week.

Container

Never move a repurposed container without first emptying it of its stock. As the container is repurposed into a temporary storage unit, some ventilation holes will have been made in its structure; ensure that it is protected while it is in transit to its new location.

Relocating a permanent warehouse

See guidance points in the Relocating stocks to a new warehouse section above.

Ensure the new warehouse is inspected while empty, well in advance of the move (a minimum of two weeks) and arrange for any identified need to be addressed before the move (wall fixtures, pest control, ventilation, etc).

The new warehouse must be mapped before the first stocks arrive at its location, so that briefed staff can easily move the goods into storage. Ensure storage systems (shelves, racks, etc) are installed before the first stock is delivered, and that water and electricity supply is arranged in advance.

Stock records

Once goods are in stock, the field logistics officer and the warehouse manager must ensure that the stock is maintained in good condition and accurately tracked until items are dispatched. Stock should be kept at manageable levels to permit frequent rotation to avoid the build-up of unused stock and losses due to spoilage and overdue expiry dates.

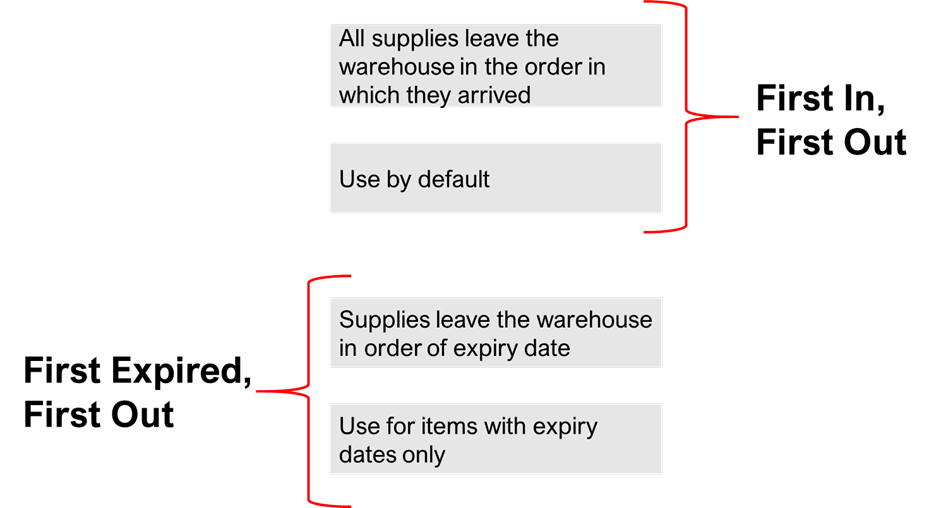

Apply the First In, First Out rule; all supplies should, in principle, leave the warehouse in the same order in which they arrived. The exception is the First Expired, First Out rule; items with expiry dates must be distributed according to their expiry date. Additionally, damaged, infested or damp goods that are still fit for human consumption must be distributed before older stocks and without delay, to avoid further loss.

All supplies stored in the warehouse must be registered on stock cards and bin cards. These cards are the primary tracking tools used in a warehouse – they follow the commodities from the time they enter the warehouse to the time they are dispatched.

Though similar, the two forms have separate functions and should not be confused. Templates for the cards can be found in the appendices, and both are discussed below. Ideally, both stock cards and bin cards should be used, especially where few items are in store and where they are in large quantities and under different .

Bin cards

A bin card must be physically attached to each grouping (a stack, pile or grouping on a shelf) of an item in a warehouse. It provides basic information about the goods:

- item type

- CTN (where applicable)

- batch number (where applicable)

- quantity

- origin

- arrival date

- expiry date

- any re-conditioning it has undergone.

Separate cards must be issued for each stack, as well as for goods with different CTNs, batch numbers or expiry dates. A grouping of one commodity (a stack) can be increased on the same bin card, as long as the goods are placed in the same stack and have the same CTN, expiry date and batch number (where applicable).

Where any of these three do not correspond, a new stack must be started, even where the commodity is the same. Every time an item with the same CTN, batch number and expiry date is received, either under a or a transfer waybill, and is added to a pre-existing stack, the quantity is recorded in the “IN” column on the bin card. The “OUT” column is used every time part of the stack is dispatched under a waybill or losses have occurred and a claim report has been filed.

The bin card is closed and removed from the storeroom when the entire stack has been dispatched, transferred or accounted for under a claim report. The old card must be filed, sorted by item code and date.

Stock cards

All commodities received or dispatched from the warehouse should be immediately registered on a stock card by the warehouse manager. These entries should correspond to a GRN, waybill or, in the event of loss, a claim report.

Every entry should bear the signature of the warehouse manager or, in the case of larger operations, a designated assistant. A stock card is less detailed than a bin card and includes stock with different expiries or batch numbers.

Stock cards can also be raised by batch number or by CTN where no bin cards are in use. It is a summary of all bin cards for goods with the same CTN and indicates the overall stock level for an item. The “IN” and “OUT” columns are completed in the same way as on the bin cards.

The warehouse manager is responsible for keeping the stock cards in a safe location in the warehouse office space and must ensure that they are filed properly (in alphabetical order, by catalogue codes or by area of the warehouse, for example) and that all stock cards that have been filled out are numbered and archived properly.

The summary of all stock cards is the stock report or stock movement report, which is used for daily, weekly or monthly reporting and for stock management.

Stock management and reporting options

Besides using the mandatory bin and stock cards, total stock levels can be monitored using different systems, with varying levels of automation and sophistication.

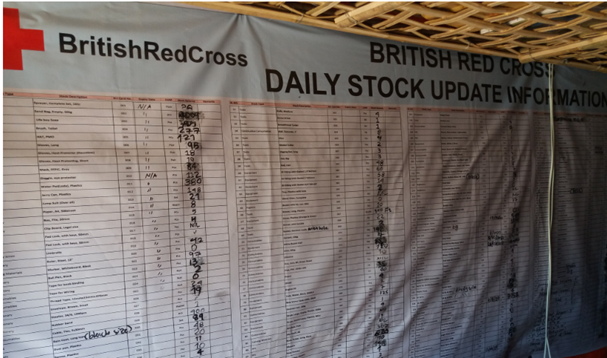

Manual stock board

This can be useful in small operations, with a limited number of items in stock and a limited number of end users. A stock board is a visual way of informing requestors of current stock levels in the warehouse and must be updated every time there is a stock movement. This system should be used only in cases where no other options are available or sustainable, and for as short a period as possible.

Excel spreadsheet stock report and analysis

Excel stock reports are useful where stocks are held at multiple locations as spreadsheets can easily be compounded to obtain a general stock overview. The frequency of update and sharing of the spreadsheets must be pre-agreed, so that the information reflects stock levels at the same point in time.

Offline databases

There are several ways to maintain local databases containing the stock information. These are maintained offline (they do not require an internet connection) and can be exchanged between locations to calculate compounded stock levels. Reports can also be extracted from these databases and shared with stock owners in Excel format. The general trend in the humanitarian world is to use this type of solution less often, as Internet connections become more widely available.

Online databases

The use of software solutions, either in a “ready-to-use” version or specifically developed for a specific user, is becoming more common.

Orders can be placed through the system, and stock levels are automatically updated from other transactions approved in the system: for example, raising a against an approved will result in an increase in stock levels, recorded against the GRN reference generated by the system, and approving a stock movement in the system will generate a waybill and reduce the stock levels.

These solutions are a considerable investment and should be developed in common across the Movement where possible, to share the costs of development and ensure consistency.

Refer to the latest version of the stock management strategy published by the for more information about the development of stock management systems.

LogIC (logistics inventory control)

LogIC is currently the system that is most widely used across the Movement, particularly in IFRC-led operations, but the IFRC and are currently looking to develop a more holistic joint stock-tracking tool. Each National Society can choose the system they use to track stock.

LogIC training is available upon request – reach out to the UK team to enquire about training options.

Warehouse performance management

The warehouse manager is responsible for overall reporting and monitoring, under the supervision of the Logistics delegate. KPIs monitored include:

| Definition | Source | Target | |

|---|---|---|---|

| Warehouse utilisation (%) | What part of the available storage space is actually utilised? | Warehouse map Stock volume information | If < 70% warehouse is being under-utilised |

| Stock accuracy (%) | What part of the stock is accounted for correctly after stock takes? | Stock take report | 100% |

| Order preparation lead time (days) | Number of days from approved request to dispatch of items | Requisitions Waybills | To be agreed locally |

| Loading/offloading lead time (hours) | Number of hours to load or offload consignments | Visitors' book | To be agreed locally |

| Claims against deliveries (units) | How many claims have been raised on shipments dispatched from the warehouse? | Waybills Claims forms | To be agreed locally |

Available to download here.

Read the next section on ERU stock management here.

Related resources

Download useful tools and templates

Download the full section here.

Mapping a warehouse

Once the storage space has been identified, it will need to be optimised for your planned needs. Areas to be included in the storage map are:

Bulk storage area

- This is where the majority of items will be stored – it can be densely organised.

- Items in most regular demand should be closest to the goods receipt/dispatch/picking areas.

Goods receipt area

- Estimate its dimensions per the expected incoming volumes: if you expect to receive items in 20-ton truckloads, make sure your reception area is large enough to store the corresponding volume.

Goods dispatch area

- Estimate its dimensions per the expected outbound volumes: if you expect to dispatch items in 20-ton truckloads, make sure your dispatch area is large enough to store the corresponding volume.

Picking area

- Depends on the dispensing units: if items will be dispatched in a smaller packaging unit than they come in, you will need a picking area (bulk construction items such as nails, bolts or medicine, as you will dispense packs or bottles in smaller quantities than the base carton quantity).

Truck docking area

- For trucks to station and manoeuvre and offload. Include level docking platform if possible.

Office space

- Ensure office space can be isolated from noise and vehicle movements and is ventilated.

- A safe path to the office space must be kept clear at all times.

Packing materials storage area

- Use to store carton boxes, pallets, wrapping and strapping materials.

Cold chain area

- For items which require specific temperature conditions.

- Move close to power supply source and ventilation.

Quarantine area

- For expired, damaged items or items pending inspection or test results.

- Must be lockable.

Sanitary facilities and breakout area

- Ensure respect for cultural norms.

Emergency exits and fire fighting equipment

- Must be signalled clearly.

Security shed/corner

- For security personnel to use during shifts and to store their work equipment. Should be located near the main entrance to the warehouse compound.

A table detailing the different areas is available to download here.

Each of the areas should be clearly separated from one another and space between stacks, racks, shelves or pallets must be included to allow for passage and cleaning.

Depending on how the goods will be handled (manually or with specialised equipment), the space between storage blocks will be different. For human handling, 1.2m is usually enough. Where specialised equipment (forklift, sack truck or hand pallet truck) is used, the manufacturer will be able to confirm the required turning circle.

Each storage unit must be at least 50cm away from the main wall of the warehouse.

Standard layouts include:

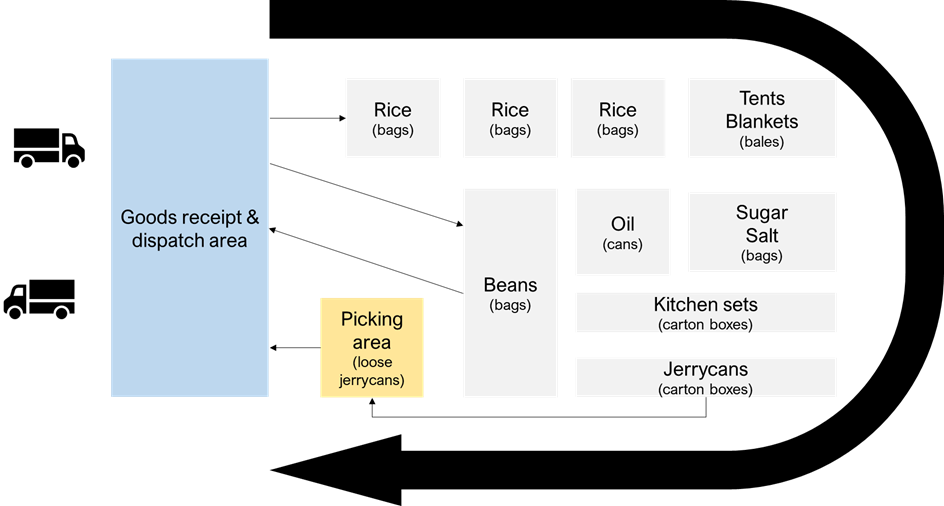

U-flow

Available to download here.

U-flow is used when the receiving and loading areas are next to each other on the same side of the building. It provides the following features:

- Because the receipt and dispatch areas are side by side, the space can be used flexibly, particularly if these activities are scheduled to take place at different times in the working day. This can save space.

- Personnel and equipment can be used in a flexible way, reducing the overall requirement for resources.

- Because the main access to the building is in one place, access and security are easier to manage.

- The building may be extended on three sides where required and where the site allows.

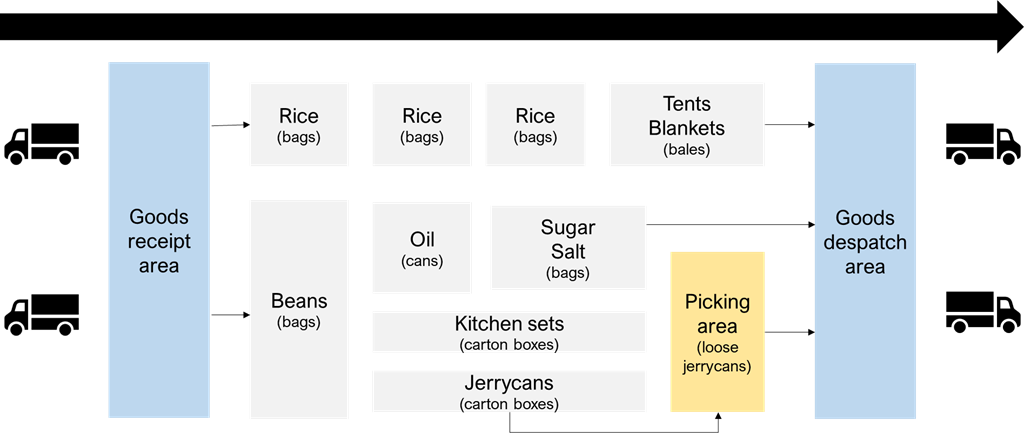

Through-flow

Available to download here.

Through-flow is used when the receiving and dispatch areas are at opposite ends of the building. It tends to be used under the following conditions:

- Where vehicles and equipment used in receipt and dispatch are of different types.

- Where the flow of vehicles around the site will be facilitated (there may be separate gates at opposite ends of the compound for example).

The warehouse manager should ensure that all areas of the warehouse are physically identified, and a map of the warehouse must be available and posted on its walls.

Equipping a warehouse

Depending on the type of goods to be stored, the activities that will take place in the warehouse and the equipment available, the warehouse will have to be fitted with office equipment, specific storage equipment, additional safe storage space and/or partitioning.

In certain cases where the warehousing activities are expected to be critical to the operation and include large volumes of items, it may be relevant to invest in handling equipment.

In all cases, the storage facility will have to be equipped with a fire prevention system.

Storage options

A stack is a pile of the same item on a warehouse shelf.

Goods must be stacked separately and sorted by programme ownership, expiry dates or final destination, for example.

A bin card must be physically attached to each stack or grouping with the same , batch number and expiry date.

Wherever possible, stacks should be placed on pallets and not directly on the floor. Where possible, they should be wrapped in plastic sheeting or tarpaulins.

Where supplies of pallets are limited, note that bagged foods are more vulnerable to humidity than canned or bottled products, so food items should be palletised in priority.

Where pallets are not available at all, items can be temporarily stacked on plastic sheeting laid on the ground.

The distance from stacks to walls and between the stacks must allow a person (or a forklift if using) to pass and be at least 50cm.

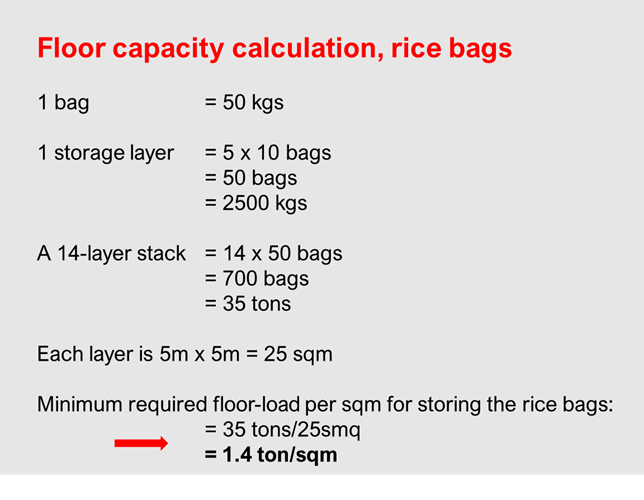

The recommended size of a stack is 5 x 5 metres and a maximum 2.5 metres high with bags stacked by 5 x 10 = 50 in each layer x 14–15 layers (= ~ 700 bags).

The stack height will be affected by the type of packaging; boxes and jute bags stack higher than woven polypropylene bags, which tend to slide. When stacking cartons, ensure that lower packages in the stack are neither crushed nor torn. Commodities packaged in tins and plastic bottles, have lower restrictions in terms of maximum stacking heights.

In addition to height restrictions, oil packages frequently indicate a recommended maximum number of rows for stacking. Check the instructions on packaging, where they exist, or consult the suppliers for information.

Where stacks are tall, it is useful to tie a rope around the top layer to stabilise them.

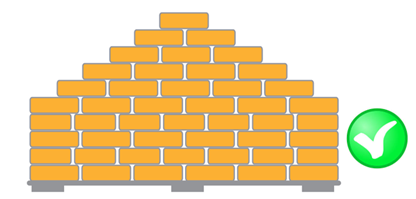

Bags that need to be stacked higher than 2.5m should be stacked up to 2.5m as shown here, with the additional layers stacked in a pyramid to avoid slippage. Plastic sheeting can be added between layers to prevent slippage.

Volumetric storage

Create a one-cubic metre container to measure sand, gravel or a quantity of construction materials in bulk. This works well for timbers, poles, bamboos and items stored in “bundles” of 100 pieces for example.

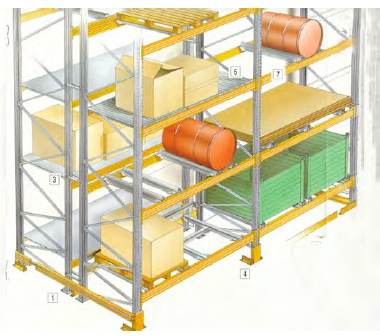

Pallet racks

Simple pallet racks usually have two or three tiers. Two tiers of pallet-racking require a clear total height of about 3 metres and three tiers require a clear total height of about 4.5 metres. It is possible to have more tiers, but sophisticated mechanical handling equipment is then required.

The benefits of shelving and pallet-racking can be combined. The bottom tier of racking may be used to store the working stock if arranged at a convenient height for manual order picking. Alternatively, a special picking shelf can be placed immediately above the bottom tier of pallets. In both cases, the upper tiers can be used to store safety stock or bulk stock. Caution: check the racks’ load-carrying capacity with their owner/manufacturer or an independent engineer before using them and check every rack regularly for signs of damage.

Keep space between the racks and the walls, ensure that the racks are stable and, where possible, fixed together and to the wall and/or to the floor.

Large racks

Large racks are useful when storing large inventories of a variety of types, and where the dimensions of pallets are not the standard dimensions of packaging. The racks pictured here have the advantage of adjustable racking height.

Leave space between the racks and the walls.

Ensure that the racks are stable and where possible, fixed together, to the walls and/or to the floor.

Shelves

Use shelves where there are a lot of small items and/or when there are items that need repacking or picking (medical supplies, kits, etc). Storage on shelves does not require mechanical handling. In tropical countries where termites attack wood, metal structures are preferred. Shelves can be taken apart and adjusted to suit the goods to be stored.

Keep space between shelves and walls to improve ventilation.

Choosing the best storage options

Bulk items (loose)

- volumetric storage

- 1,000 kg = Variable volume

- volume defined at item level, as item density varies

- 1,522 kg of gravel = 1cbm

- 1,922 kg of sand = 1cbm.

Food in bags (grains. flour, sugar, salt)

- stacked on pallets, with chicken wire between pallet and supplies

- 1,000 kg = 2cbm.

Food in cans or bottles

- stacked on pallets

- 1,000 kg = 1.5 cbm

- ask manufacturer for maximum stacking layers.

NFIs in boxes

- stacks

- adjustable racking

- check stackable height where items are fragile.

NFIs in bags or bales

- stacks (fenced)

- adjustable racking

- 1,000 kg = 8-10cbm

- stacks if stable

- adjustable racking preferred for bales.

Construction materials

- bundles of xx units

- 1,000 kg = Variable volume

- keep stacks fenced with timbers or wiring.

Medical supplies (drugs)

- large racks for main storage

- shelves for picking units.

Medical equipment

- Pallet racks or large racks.

A table detailing the best storage options is available to download here.

In addition to the above, note that to store medical and/or food items you will likely need:

- cold chain equipment: passive (ice packs or other isotherm systems) and active (power-generated)

- a locked storage space for controlled substances

- a quarantine area equipped with shelves/racking.

See the storage of food and medical supplies sections in Managing a warehouse.

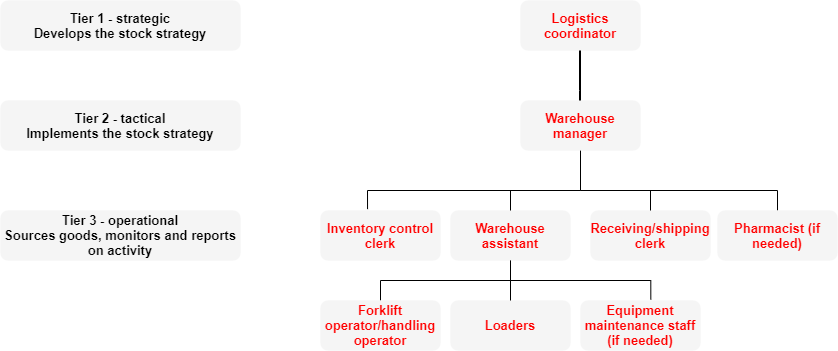

Manning your warehouse

Based on the process mapping exercise (part of the stock strategy definition – see the How? section of Stock strategy definition in Building a stock strategy), adequate resourcing will be required for the operation of the warehouse.

The size of the warehouse team will depend on the size of the operation, and the allocation of tasks should be adjusted accordingly (one member of staff may cover several of the below functions). Below is a standard organisation chart including all the skills needed to operate a warehouse.

Available to download here.

Recruiting a warehouse team

Standard job descriptions are available on request from the international logistics team.

The logistics team can provide examples of written tests for recruitment on request, should you need them.

Guards and security staff and services can be either hired as staff or day labourers, outsourced as a service or included in the lease of the warehouse. Where guards are hired as staff or day labourers, the warehouse manager will have to define working patterns and shifts (rota). Ideally, these should be captured in a guards’ shift planner.

Some situations will call for a set of core permanent staff, with the arrangement for temporary staff to meet periodic increases in demand or workload. Holding a register of daily workers with contact details and specific skills, managed by the warehouse manager only, can be useful.

Host National Society (HNS) volunteers can also help in the warehouse during periods of high activity, but this must be agreed with the HNS and their procedures and practices must be observed in terms of volunteer hours, incentives and payments. Do not engage volunteers as regular staff without prior approval from and consultation with the HNS.

| Advantages | Disadvantages | |

|---|---|---|

| Hired as staff | Permanent staff with benefits Can be trained and retained | Must manage working hours and performance directly Ensure status in country allows recruitment in own NS's name |

| Hired as daily labourers | Flexible workforce Wide pool to recruit from HNS can provide volunteers | High turnover of staff |

| Outsourced | Flexible workforce Guaranteed professional service | Limited control over allocated resources - competition with other clients |

| Included in warehouse lease | Not included in head count No direct management | Limited control over allocated resources No control over ethical management standards |

Available to download here.

Managing the warehouse team

Warehouse managers are permanent staff members, staff or volunteers. They are responsible for all activities related to stock movements: the reception, storage, release, dispatch and recordkeeping for all goods.

The warehouse manager defines, schedules and coordinates the activities and resources that need to be available to deliver the mission of the warehouse. They also oversee security arrangements, control the recruitment of day labourers and manage the schedules, payment, performance and training of all warehouse personnel.

Regular team meetings should be held, organised by the warehouse manager:

| Frequency | Attending | Purpose |

|---|---|---|

| Monthly | Complete warehouse team and logistics delegate | Monitor performance against set objectives and discuss updates on projects |

| Weekly | All warehouse staff | Warehouse manager to present operational objectives of the week and reflect on past week |

| Daily | Individual briefs to loaders and receiving/despatching staff | Allocate daily tasks |

Available to download here.

Where daily labourers are regularly recruited, a system must be in place to request the number required each day, record their attendance and report to finance for payment. For example, the receiving/shipping clerk should request through a daily worker request form, signed off by the warehouse manager. Attached to daily worker record sheet, the whole file should be submitted to finance for weekly payment at an agreed time. As far as possible, day labourers should only be hired as security guards, cleaners and loaders.

Read the next section on Managing a warehouse here.

Related resources

Download useful tools and templates

Download the full section here.

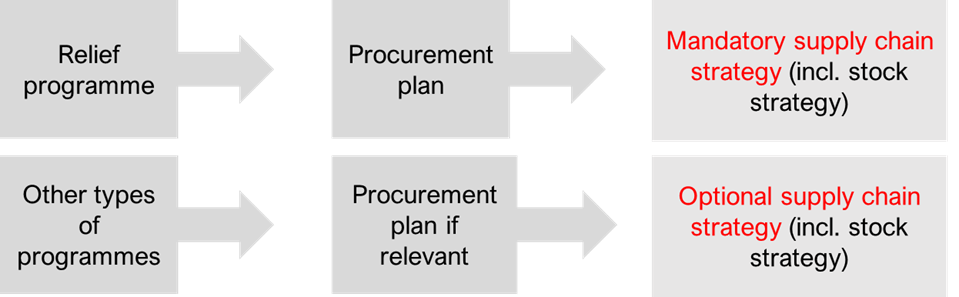

Assessing the warehouse requirement (number, location and operation)

During the design phase of a programme, a stock strategy should be developed, including the potential requirements for warehousing. This should fit into the wider supply chain strategy for the programme (see supply chain strategy template and guidelines).

Warehouses are needed when the time required to purchase and mobilise relief items is expected to be lengthy or when responding to a protracted crisis where the risk of disruption to the supply chain is high.

A network of warehouses may also be required to ensure the rapid and efficient delivery of relief supplies. Since most British Red Cross programmes are short-term (a maximum of several years) the need for a new permanent warehouse is rarely justified, although it can be considered as a long-term solution for an supporting future programmes.

Stock strategies must be in line with organisational strategies because holding stock with a projected high value is a risk to the organisation. Other supply chain options, such as the delivery of goods taking place closer to the required time, are sometimes preferable.

Programmes should not be built around the stock strategy (What do we have?) but a stock strategy around the programme (What do we need?).

Available to download here.

Quantity and location of warehouse(s)

- type of items to be stored

- scale of operation and required stock levels

- geographic and seasonal conditions

- distances to programme site(s) and supply entry points

- infrastructure available

- availability of transport services

- lack of other storage options (vendor-managed inventory, 3rd party warehousing etc.).

-> Number and location of warehouses required for an operation

Stock strategy definition

View the stock strategy definition diagram here.

During the planning phase, the programme team should provide a range of information to enable logistics to develop a stock strategy.

What?

Storage requirements vary depending on type of items.

Medical supplies and drug shipments can contain small and high value items, many of which have a limited shelf-life.

A secure area is required, and close attention must be paid to expiry dates.

Antibiotics and vaccines require temperature-controlled cold storage arrangements, with sufficient capacity and a reliable power source, with a back-up option.

Combustible items such as alcohol and ether must be stored separately, preferably in a cool, secure shed in the compound and outside the main warehouse.

Non Food Items (NFIs) can usually be stored in bulk with no specific storage or handling limitations.

Dangerous goods such as fuels, compressed gases, insecticides and other flammable, toxic or corrosive substances, are hazardous.

International regulations require specific markings to identify their dangers.

Consider the volumes to be stored: the quantity to be stored and the frequency and size of deliveries and dispatches will influence the stock strategy definition.

Consider whether the stock strategy will involve holding and handling kits in stock. If so, how much kitting activity is expected to take place in the warehouse? Kits are often used in emergencies, when the aim is to provide large quantities of a standard set of items to large numbers of people.

The IFRC standard product catalogue (SPC) includes a wide variety of kits, normally provided as full kits by long-term suppliers sourced by the .

Detailed information on handling hazardous substances can be found here.

Detailed information on managing kits can be found here.

Where?

Where is the programme being implemented and where are the goods required?

Think about:

The geographical location (is access by road, sea or air?)

Is it a rural or urban area?

The number and location of sites

The security situation

What warehouses are available, in the region and country, in and outside of the Movement, and what are their associated costs?

What are the options and costs of renting commercial warehousing?

What are the options and costs of using temporary Rubb Halls (mobile storage units, or MSUs) or containers (a last resort, due to cost, storage conditions and their difficulty to manage)?

-> Gathering this information will allow for a decision on where along the supply chain to position the warehousing (at global, regional, local or field level).

Consider the option and cost of having vendor-controlled inventory (VCI). Where there are long-term relationships with suppliers, suppliers can hold stock for the in their own warehouses. The stock is prepaid by the RCRC and released with a simple stock request. In this case, requirements need to be carefully calculated and transport costs closely estimated as they are likely to be higher. A VCI strategy is viable where the variety of items required is small and can be supplied by a maximum of two or three suppliers, who are willing to collaborate and consolidate shipments to control transport costs.

When?

A detailed timeline (start and finish dates for the programme), with requirements scheduled throughout the programme’s implementation will help (this can usually be inferred from a good procurement plan).

Details of the frequency of deliveries and dispatches will also be helpful here, as well as estimations of the time needed to fulfil the ordering cycle. It is advised to estimate the average throughput of the warehouse in order to support the dimensioning of the required storage space (how large will orders in and out be on average helps define the dimensions required for reception and despatch areas for example).

Try to define durations for standard warehouse processes such as:

- time from delivery at warehouse to storage location in warehouse (dock to shelf IN)

- time from receipt of requisition to availability to dispatch (shelf to dock OUT)

- stock takes cycles and associated warehouse closures.

How?

Design the reception, requesting, dispatch and reporting processes at an early stage of the programme design, to inform the level of human, financial and administrative resources required.

Questions to ask when defining a warehouse resourcing strategy:

- How will deliveries be managed?

- Who will process them and how will they be documented?

- How will requests from users be managed?

- When will they be received by the warehouse team and how will they be documented?

- Who will prepare the orders – in what timeframe, at what frequency, with deliveries done where – at the warehouse door or at the site?

- How will dispatch operations be managed?

Who will oversee the booking of transport and how will transport be booked?

How will dispatch be documented, who will validate dispatch and how will delivery rounds be organised? - How will stock reporting be compiled and communicated?

What information will be recorded and what will the reporting cycle be – weekly, bi-monthly or monthly?

How much?

The setting of minimum stock levels must be discussed between the logistics and programme teams.

The logistics team should make a recommendation based on the programme’s requirements, to be assessed by the programme team in view of objectives, budgets and timeline.

Factors to consider when setting a stock minimum:

- total population in area

- total population at risk in case of disaster

- types of disasters that may occur

- probability of disasters occurring

- type of items needed

- replenishment time = time taken to get relief items from HQ or other partners in the area

- response capacity of the branch – number of active volunteers trained in emergency response and/or logistics

- available storage space

- available transport.

There are a set of criteria that support defining the ideal inventory level. Usually these include:

The budget available for warehousing and transportation costs. Limited resources will influence what type of warehouse activities the programme can afford, in terms of storage space, transportation possibilities and human resources.

Clarifying the different purposes of the inventory. See table:

| Working stock | Safety stock | Preparedness stock | |

|---|---|---|---|

| Purpose | To meet normal or expected demand for humanitarian goods between deliveries. | To mitigate the risk of stock-outs in the period between deliveries (due to increased demand or decreased supply). | To meet sudden increases in demand. |

| Depends on | Level of demand Order frequency Vehicle spare parts, fuel | Unpredictability of demand Unpredictability of supply Risk appetite | Organisational policy Availability of funds and resources to manage Household items |

Available to download here.

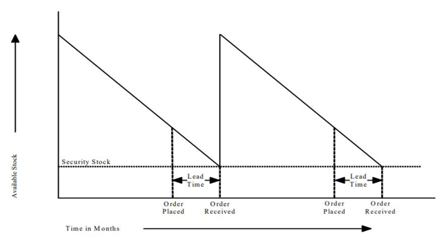

Understanding the stock-time curve: this is about managing the supply and demand. The usage rate of stock can vary and it is important to identify and record times when the safety stock is used. See the below diagram that illustrates the stock-time curve.

Available to download here.

Using forecasts: estimating demand and supply capacity will support the accurate definition of order quantity and frequency. Forecasts will be based on the organisation’s strategy (how they define preparedness requirements in the stock strategy paper), assessment reports (how they define working stock levels in assessment reports) and short-term forecasts and risk assessments (how they define safety stock levels in the programme plan).

Choosing an ordering system: choose the trigger for placing a replenishment order. Apart from the stock level and the usage rate, two factors can determine what is the right time to place an order:

Order placement and delivery lead time

Order quantity

Considering the shelf life of items held in stock in the ordering cycle.

To determine the order frequency and quantity, the free stock level is the most important information to have at hand.

Physical stock on hand

+stock on order from suppliers

+stock in transit

-reserved stock

=Free stock level

Reserved stock is stock already allocated to orders in preparation, or stock otherwise reserved for special purposes.

There are two different “standard” re-ordering systems:

Two-bin system:

- This is best used for low-value items.

- Stock is kept in two separate bins (50 per cent in each).

- When Bin One is empty, start taking from Bin Two and replenish quantity for both.

Periodic review system:

- Replenish system options:

- Top-up system – at each review, place an order to top up from available stock to a target stock (agreed with stock owners).

- Minimum stock system – place order when free stock is less than minimum stock (a “re-order point”).

Bear in mind that other factors can impact the order quantity, such as the minimum order quantity set by suppliers or the available budget.

Remember

Reorder quantity (ROQ) = average daily usage x average delivery lead time

Reorder point (ROP) = ROQ + safety stock

When ROP is reached, an order should be placed to the ROQ quantity calculated.

Safety stock must be an organisational decision (expressed in days’, weeks’ and months’ usage), based on risk appetite.

ROQ should be calculated with daily, weekly and monthly numbers consistently across the calculation. This calculation takes consumption during both the order lead time and consumption in general into account but variations (higher or lower consumptions) will not be incorporated.

A concrete example:

The initial situation:

In the Sinapai branch, they decided to stock at least 50 family kits (=50 lanterns, 50 buckets, 50 jerry cans, 150 blankets…)

Their actual stock is 60 complete family kits.

The distribution:

After a small disaster, the branch distributed 10 family kits with 15 extra jerry cans and 10 extra blankets.

The new situation:

They only have 35 complete family kits left.

Replenishment needs:

They absolutely need to replenish 15 jerry cans and 10 blankets to reach their stock minimum of 50 complete family kits.

General considerations for stock strategy definition

- Are there other programmes planned (by British Red Cross or another ) with similar activities that could potentially fit into one stock strategy? If yes, ensure strategies are aligned and well embedded.

- If stock strategy poses too high a risk or does not provide , can alternative modalities be considered? Think of vendor-controlled inventory, or stock managed by partners.

- Are there any previous experiences with this or context we can draw from? Consult with other programme managers.

- How does the stock strategy support development of the capacities of the HNS? How is it aligned with its strategic objectives?

- Logistics can advise ordering extra items for safety, but this must always be agreed with the budget holder (or programme manager) before placing the order.

Estimating your storage space needs

Once it is confirmed that one or several warehouses will be needed to deliver the objectives of the programme and with the storage location(s) agreed, you will need to estimate the storage needs.

The size and type of the warehouse will depend on the required storage capacity for an operation and is determined by the maximum quantity (in tonnage and volume) of supplies to be stored.

This may be different from the total quantity required for the whole operation. The quantity of stock to be held and the number of warehouses to use will vary along the duration of the programme and is determined by the programme plan.

The required storage volume depends on the weight-per-volume ratio of the goods. The area occupied in the warehouse by one item depends on its volume, the height of the storage space and the maximum permissible load-per-square-metre of floor space.

To illustrate how volumes can vary dramatically, below are some examples of the average volume in cubic metres (CBM) of one metric ton (MT) of the following items:

| Items | 1 MT (1 metric ton = 1000kg) |

|---|---|

| Grain, flour, sugar (bagged) | 2m³ |

| Medicines (Average for bulk shipments and medical kits | 3m³ |

| Vegetable oil (in drums or tins) | 1.5-2m³ |

| Blankets in pressed bales (approx 700) | 4-5m³ |

| Blankets in unpressed bales | 8-10m³ |

| Clothes (in bales) | 7-10m³ |

| Tents (approx 25 family tents) | 4-5m³ |

| Kitchen utensils (in 35-40kg boxes) | 4.5m³ |

When calculating storage requirements, only 70 per cent of the total warehouse’s surface capacity should be considered as available for storage space. The remaining 30 per cent is used to ensure proper ventilation, passageways, handling space and repackaging areas.

Warehouse storage capacity:

Approximate storage capacity of the warehouse = Length x width x (height – 1m) x 70%

How to calculate the required storage capacity:

Add the total weight and total volume of the items to be stored and use the volumetric info from the above table (CBM per MT requirements)

Divide the total CBM by 70 and multiply by 100 to calculate the total warehouse volume needed. Assume 2m stacking capacity. Include truck docking areas (in addition to the storage spaces).

View and download a table demonstrating the calculation of required storage capacity here.

Estimating your floor-load capacity needs

No more weight than that specified in the warehouse leasing contract should be stacked per square metre of floor space. The permissible load at ground-floor level will normally be 1,000–3,000kg/m2, but on upper floors (or ground floors where there is a crawlspace or basement) it can be as low as 500–800kg/m2.

Always do a physical check of the floors – when floors are damaged, their capacity will be reduced.

Calculating stock turnover and adjusting target stocks

It is good practice to periodically review the target levels of stock that have been set for a programme and set a stock turnover target (per item and per period) to ensure that the stock targets remain relevant to the operation.

The stock turnover target can vary from one item to another and depends on the context of the operation. At the British Red Cross, the stock turnover target on stocks pre-positioned for emergency response is equal or greater than two per year: to consider stocks of a specific item as relevant, the ratio of items issued out to the average inventory level in the year must be greater than two.

A basic way to calculate the average inventory is the beginning-of-year inventory plus the end-of-year inventory, divided by two:

average inventory = (inventory at beginning of year) + (inventory at end of year) ÷ 2

stock turnover ratio (per item) = total quantity of stock issued out (1 year) ÷ average inventory (1 year)

A few questions to guide the stock review to adjust target stocks:

- Of the total stock, how much has been used (requested or issued stock divided by total stock, in percent) over the period observed?

- What is the total percentage of stock loss (expired, damaged, and lost stock divided by total stock, in per cent)?

- What is the ratio of used storage area vs available storage area in the warehouse?

- What are the objectives of the programme the stock serves?

- What are the relationships of the with established suppliers in the area? Could they provide or respond to needs within a maximum of 48 hours?

Read the next section on Sourcing a warehouse here.

Related resources

Download useful tools and templates

Download the full section here.

The 11 major rules of running a warehouse:

- Rotate stock so old goods are used first: FIFO (first in, first out). If goods have an expiry date, use FEFO (first expired, first out).

- Stack goods safely.

- Plan the layout of goods for easy access and finding them again.

- Record all movements or losses on the correct forms.

- File all papers immediately.

- Plan ahead: what goods, staff and transport will be required in the next day, week or month?

- Keep goods secure.

- Keep warehouse clean, with daily, weekly and monthly cleaning.

- Dispose of spoiled goods correctly and quickly.

- Communicate objectives, plans, progress and issues effectively.

- Conduct physical inventory on a regular basis.

Definition:

A warehouse is defined as a planned space for the storage and handling of goods and materials. Goods and materials stored in a warehouse are considered as stock, which is also called “inventory”. Warehouses are an integral part of the supply chain, their main purpose being to serve as physical transit points between supply (delivery from suppliers) and demand (end-users or beneficiaries).

Where needed, warehouses allow for the breakdown of bulk deliveries across different requestors or into phased deliveries, and for the combination of loose items into kits to meet beneficiaries’ needs.

A well-managed and well-positioned warehouse allows for speedy responses to both planned and unplanned needs and ensures that both inventory and staff are ready to respond to planned and unplanned needs.

Functions of a warehouse

View and download a detailed diagram of warehouse functions here.

Different types of inventory

It is important to be aware of the difference between stock (inventory), office supplies, office equipment and assets:

| Stock | Office supplies | Equipment | Assets | |

|---|---|---|---|---|

| Definition | Consumable items that are tracked and stored until use or distribution | Temporary or disposable consumables, food or cleaning products required on a day-to-day basis, for use in the office or residence | £1,000 or > 3 years useful life or Powered by electricity or Incurs running costs or Defined as asset by donor | |

| Examples | Programme supplies for direct distribution Office supplies for distribution to beneficiaries, partners Vehicle spare parts, fuel | Stationary Office cleaning materials Food for office consumption | Furniture Housing equipment Household items | Owned property Vehicles Comms equipment IT hardware Large household appliances |

| Reporting requirements | Stock report | None | Property register | Asset register |

| Storage location | Warehouse | In the office | In use or in storeroom* | In use or in storeroom* |

*The storeroom is typically a small room in the office where a small stock of office supplies is kept

Available to download here.

Purposes of holding stock

The main purpose of stock is to de-couple supply and demand in an operation that requires the provision of pre-determined goods and materials.

In an ideal world:

- exact needs are known

- suppliers are reliable

- supply is stable

- infrastructure is stable

- there is little to no need for inventory.

In the humanitarian world:

- needs fluctuate unpredictably

- suppliers are liable to multiple risks (environmental, political, financial)

- supply is often interrupted

- infrastructure is exposed to multiple risks (environmental, political, financial)

- inventory acts as a buffer against structural risks.

Stock ownership

Generally, stock is owned by its original requestor (the person who pays for the goods) and physical management of items and materials is delegated to logistics.

This means that logistics cannot choose to increase or decrease stocks unilaterally and that updates on inventory must be shared between the logistics team and the owners of the stock managed in the delegation.

In that sense, logistics is responsible for the inventory it holds for others, but requestors and programme managers are accountable for the type and quantity of items they require logistics to hold in stock for their use.

Stocks management – roles and responsibilities

RACI matrices are used throughout this manual. They break a process into steps, specifying who is Responsible, Accountable, Consulted and Informed at each step of the process.

| Responsible | Accountable | Consulted | Informed | |

|---|---|---|---|---|

| Warehousing & Stock Management | Warehouse staff | Requestor Budget holder | Programme team Health and safety | Logistics team Finance team |

Available to download here.

The valuation of inventory is critical for the organisation to manage the risk of ownership of stock in general, and in particular to support the definition of insurance requirements.

Financial management of stocks

For financial management of stock in the UK, refer to the Bulwick warehouse SOP, ERU kit SOP, UKO stock management SOP, RLU stock management SOP and the Balance sheet guidance note.

More information on the Regional Logistic Unit (RLU) and Emergency Response Unit (ERU) stocks management can also be found in the RLU stocks and ERUs chapters of the Manual.

The general concepts to bear in mind are:

- Inventory held by international logistics for preparedness purposes is valued in collaboration with the logistics finance business partner, based on procurement information shared by the logistics team.

- The value of inventory held by logistics sits on the British Red Cross balance sheet from the moment stock is received to the moment it is dispatched for use.

- When stock is dispatched for use, the value of the dispatched items is charged to its requestor and taken off the British Red Cross balance sheet.

- When stock needs to be disposed of, logistics must use a write-off form to record the disposal. The value of the disposed items is usually charged to the logistics budget and taken off the British Red Cross balance sheet.

See the Disposing of and writing off stocks and Writing off obsolete assets sections for more details on stock write-offs.

Note: it is recommended that the members of the logistics team who manage stock regularly meet with both their requestors and the finance team to review current stock type, levels and locations, discuss proposed changes (if any), ensure budget management and reconcile stock. In the British Red Cross, the logistics team meet with owners of the stock they manage (ERU kits, RLU representatives) and with their finance business partner on a regular basis.

Stock positioning

Within the Red Cross Movement, stocks are held at different levels and the processes to follow to access stock vary between levels of storage:

Country level

- This is stock that is available in country.

- Locally available stock can belong to the country’s or to a partner NS and would include the kits that a chooses to hold for -led responses.

- NS that do not hold ERUs may also have stocks available in country, either for ongoing programmes or for preparedness purposes.

Regional level

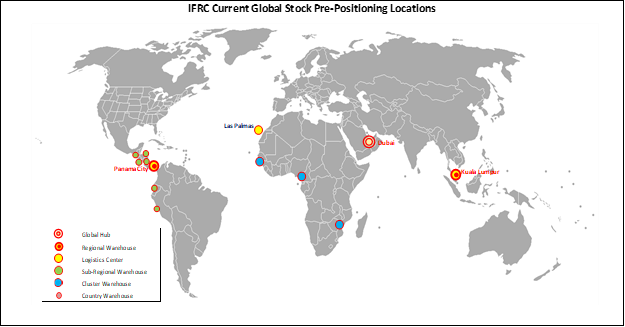

- This is stock that is held in regional hubs.

- In RLUs (Kuala Lumpur in Asia, Panama City in Americas), stocked by the IFRC and other PNSs and managed by the IFRC.

- In sub-regional warehouses or in decentralised regional stores (“cluster warehouses”), in Harare, Douala and Dakar.

Global level

- This is stock that is held in IFRC-managed global hubs.

- The Dubai and Las Palmas logistics centres are “global hubs”, serving all regions equally.

The IFRC’s global stock strategy aims are:

To cover the initial needs of the immediate aftermath of any disaster, the IFRC, with the stock pre-positioning of their members in the different RLU, has pre-positioned emergency response stockpiles in their network of regional warehouses across the globe, which could support up to 450,000 people at anytime and anywhere.

Read the next section on Building a stock strategy here.

Related resources

Download useful tools and templates

Download the full section here.

Warehousing

Definitions and concepts

Learn more in the Definitions and concepts section.

Stock safety

Learn more in the Managing a warehouse section.

Building a stock strategy

Learn more in the Building a stock strategy, Sourcing a warehouse and Setting up a warehouse sections.

Storage options

Learn more in the Sourcing a warehouse and Setting up a warehouse sections.

Health and safety in the warehouse

Learn more in the Setting up a warehouse, Managing a warehouse and Health and safety in the warehouse sections.

Roles and responsibilities in stock management

Learn more in the Definitions and concepts section.

Stock audit requirements

Learn more in the Stock takes and reconciliation and Disposing of and writing off stock sections.

In-kind support to the Red Cross movement

Learn more in the ERU stock management, RLU stock management and Releasing stock sections.