Stock management with the IFRC

Each charges a monthly fee to the British Red Cross for holding and managing pre-positioned stocks. Additionally, stock movements initiated by the British Red Cross are charged through pre-agreed logistics services requests (LSR), which provide an indication of the cost of moving the stock, allow the logistics lead ( or ) to raise a against the estimated costs and eventually pay the ’s invoice. It should be noted that real costs can be far from the quoted costs, not least because VAT is not included in Agresso POs. A variance of more than 10 per cent between a PO and an invoice will require additional approvals in Agresso.

Annual storage costs are budgeted in the British Red Cross logistics team budget, and logistics issue an annual PO for those services to each OLPSCM, against which monthly invoices sent to are reconciled. This process is managed through the logistics team and SSC, with support from the international finance team. All costs related to the storage of pre-positioned stocks are charged to the logistics budget.

Note: invoices for storage fees and services agreed through LSRs are sent from Geneva, usually with a delay of a month or two. For more details on this, see the British Red Cross management of stocks section below.

In exchange for the costs charged to the British Red Cross, IFRC provides storage space and manages the storing, rotating, shipping, receiving and quality assurance of British Red Cross stocks. IFRC also sends monthly and year-end stock reports. In addition, British Red Cross logistics visit two OLPSCMs each year and conduct a stock and warehouse audit. Reports are available from the logistics team. The audit consists of a spot check on stocks and a standard warehouse audit, focusing on the storage conditions and systems in place in the OLPSCM.

Note: some of the OLPSCM warehouses (including Kuala Lumpur and Dubai) offer quality assurance services and have facilities to perform quality tests on specific items delivered to their warehouse. This needs to be arranged and comes at a cost – for more details, contact the in the logistics team.

British Red Cross management of stocks

The British Red Cross manages the pre-positioned stocks with the operational support of the . Within the logistics team, the is tasked with managing the stocks that are pre-positioned at the .

The management of pre-positioned stocks by logistics is described in the standard operating procedure, while the financial management is done in collaboration with logistics’ finance business partner. The financial aspects of managing those stocks are captured in the balance sheet guidance document.

In case of any questions, contact the in the international logistics team.

Requesting for stocks from the

There are various ways of accessing the British Red Cross pre-positioned stocks. Agreements and standard operating procedures are in place to cover both issuing mechanisms.

Pledging stocks

When a disaster occurs, the usually issues a mobilisation table (a ‘mob table’). The mob table is designed to list all in-kind requirements to fulfil the IFRC’s emergency plan of action (EPoA) and emergency appeal (EA) and is issued to Partner National Societies who can choose to pledge items against the listed needs.

In this case, the pledge must be agreed with the emergencies team and with the regional team (usually the disaster management coordinator) during an emergency task force (ETF) meeting. Ultimately, the decision to pledge stocks against a mob table lies with the operational lead (this would be the head of region or the global response manager, depending on the context of the emergency). The must be informed ahead of the ETF so they can provide the relevant logistics coordinator with sufficient stock information to share in the ETF. This information will include, but may not be limited to:

- list of items in stock and quantities

- indicative cost of items and shipping costs to deliver them to the operation

- indicative delivery lead time to country of response for all items

- indicative replenishment lead time for all items.

It is an ETF-made decision to pledge any of the available items to the IFRC-led response. When stocks are pledged, they are essentially donated to the IFRC. All costs associated with the stock and its movement will be charged to the budget codes, as advised by the operational lead nominated in the ETF. It is worth noting that pledges can be made against British Red Cross pre-positioned stocks in the but other items can also be pledged, in which case the UK-based logistics team will source the pledged items through a procurement process. The decision to pledge items beyond those in stock is made based on cost, lead time and the specific needs of the operation (where they are not fulfilled by standard items).

Following the decision to pledge, the LOGE and/or the logistics coordinator manage the release of the pledged stocks from the relevant OLPSCM into the operation, initially through an (see the RFA guidance note). It is important that this is done with the input of the LOGE for the following reasons:

- The LOGE holds the relationship with the OLPSCM.

- The LOGE maintains records of pre-positioned stocks together with logistics’ business partner and is best placed to know the cost of stocks and how to allocate them in the stock balance sheet.

- The LOGE will be tasked with the replenishment of the stock in the OLPSCM. To avoid any loss of information or time, it is preferable that they are the lead on any stock movements in or out of the OLPSCM.

Selling stocks

Any Movement partner can request stocks from the . External organisations can also access Red Cross stocks through the , who will contact the most appropriate stock owner to arrange the terms of the donation/sale.

In this case, they would reach out to the OLPSCM teams, who would determine which stock is most appropriate (for information about different stock sources in the OLPSCMs, see the IFRC’s OLPSCM offer and system). They may then contact the best-placed stock owner to ask to buy some of their stocks.

When the request comes to the British Red Cross, it will be sent to the LOGE, who will seek approval from the emergencies team (usually the global response manager, as owner of the pre-positioned stocks). If approval is granted, the will get back to the OLPSCM with the details of the cost of the items, and the OLPSCM will issue a purchase order for the items.

After confirmation that the stocks have left the OLPSCM is received (a signed waybill), the LOGE commences the replenishment process, using a REP form (see the Replenishing stocks in the OLPSCMs section below).

Note: for more information on the stock balance sheet, see the balance sheet guidance note.

It is also possible for the British Red Cross to access other stocks (through pledges or purchases), or indeed Federation stocks through the mechanism that applies to all other National Societies: a request must be placed to the IFRC via the LOGE, detailing items, quantities and country of delivery. In this case, stocks will be sold to the British Red Cross.

Replenishing stocks in the

After stock items are released from an warehouse, they need to be replaced by new stock – this is called replenishment. If the agreed stock target for a specific item is lower than what was previously in stock, the items that were released will not be replaced.

Ideally the stock should be replaced like-for-like (in terms of quality and quantity, with specifications matching the standard product catalogue), but there may be a decision to postpone or adjust the replenishment for one or more of the below reasons:

- Minimum order quantity: some suppliers only accept orders above an agreed quantity.

- Procurement optimisation: where other stock movements are planned or being arranged, the will compile all quantities before placing the replenishment order.

- Specification reviews: specialised items may require a review of specifications before the British Red Cross decides to replenish them into the stocks.

To replenish stocks, the LOGE will raise a and have it signed off by logistics, emergencies and finance. For more details about the REP process, refer to the OLPSCM standard operating procedure (contact the British Red Cross international logistics team).

The process to follow is slightly different when a new item needs to be added to the pre-positioned stocks. This must be done through a request for action (RFA) which must be approved by logistics (the head of logistics or senior logistics manager, depending on the amount), budget holder and finance business partner.

The LOGE will manage the order and arrange freight to the relevant OLPSCM, using the shipping instructions shared by the OLPSCM. The LOGE will communicate order details with the OLPSCM, so they are informed ahead of the delivery.

The LOGE provides updates on ongoing replenishments in the logistics status report on a weekly basis.

For more detailed step-by-step guidance, refer to the OLPSCM standard operating procedures.

Read the next chapter on Emergency Response Units here.

Related resources

Download useful tools and templates here

Download the full section here.

The IFRC’s offer and system

The manages warehouses globally to pre-position emergency response stocks in all regions of the world using Regional Logistics Units (RLUs). See the Stock positioning section of the Warehousing chapter for more details.

The IFRC’s stock pre-positioning strategy takes several variables into consideration, including turnover (see the British Red Cross stocks in IFRC’s OLPSCMs section below for more details) and usage.

The stocks pre-positioned in the IFRC’s global warehouses are held through various mechanisms:

- Federation-owned stocks (FOS): items belonging to IFRC, stored in IFRC-managed warehouses.

- Vendor-consignment inventory (VCI): items owned by suppliers but stored in IFRC-managed warehouse.

- Supplier-reserved stocks (SRS): items stored at suppliers’ facilities, reserved for IFRC purchases.

- Partner National Societies’ stocks (PNS): items owned by PNS, stored in IFRC-managed warehouses.

Through the global logistics service (GLS) agreement, IFRC offers to hold stock for other National Societies in those warehouses. Each warehouse is managed by the and operates following their own standard operating procedure. Copies of each OLPSCM’s standard operating procedure are available to stock-holding upon request.

This stock is owned by the PNS but managed by the IFRC staff in the region. The GLS defines the terms and conditions of this relationship; there are costs associated with the storage, handling and shipping of PNS-owned stocks. In return, the IFRC offers stock management services, such as stock rotation, quality control at reception, consignment preparation and freight services. The OLPSCMs share monthly stock reports and annual stocktake reports with stock-holding PNSs and participate in their stock strategy upon request.

British Red Cross stocks in IFRC’s OLPSCMs

The British Red Cross holds stock in four of the ’s regional warehouses. This corresponds to the areas of focus defined in the British Red Cross international strategy and to the countries where the British Red Cross maintains ongoing partnerships:

| Warehouse location | Region |

|---|---|

| Harare, Zimbabwe | East and Southern Africa |

| Panama City, Panama | Americas and overseas branches (OSBs) |

| Kuala Lumpur, Malaysia | Asia |

| Dubai, UAE | MENA-MED (Middle East, North Africa and the Mediterranean) |

The variety of items the British Red Cross pre-positions in each warehouse varies, but they are mostly non-food items (NFIs) and follow the IFRC standard product catalogue specifications. The mix of items in stock in each location varies based on regional context, overall stock targets and British Red Cross budgetary constraints, on the IFRC’s access to stocks in the region and on stock-holding and the resources available to manage stocks.

The type and quantity of items that the British Red Cross pre-positions in each location is agreed with the emergencies team and the regional teams on an annual basis through the stock strategy review process (see the British Red Cross stock ownership, strategy and review section below).

The quantities held in stock in each location are agreed on an annual basis, with suggestions made by the logistics officer for global emergencies (LOGE), based on several variables:

Variable

- Annual stock turnover.

Rationale

- Rate at which stock is issued and replaced. This should be more than one, or the set stock target is too high and stock will sit in warehouses for too long before it is used, running the risk of becoming damaged or obsolete.

Variable

- The IFRC’s stock strategy and access to other forms of ownership (, , ) and other stock strategies where possible.

Rationale

- The British Red Cross will try to bridge gaps between the IFRC’s global stock strategy and other partners’ ability to pre-position stocks.

Variable

- Replenishment lead times.

Rationale

- The quantities held in stock will depend on lead times to source more of the same: if the lead time is longer than the time it takes for stocks to be depleted, then stock levels will be higher. If the market is able to supply replenishment items quickly, then small quantities can be held in stock.

Variable

- Historical demand for stock.

Rationale

- Items in higher demand will be stocked in larger quantities.

British Red Cross stock ownership, strategy and review

The stock that British Red Cross pre-positions in units belongs to the British Red Cross emergencies team and is managed by the international logistics team. The has direct relationships with the warehouse team in each OLPSCM and regular meetings are held between British Red Cross and IFRC staff to report on stock status and stock movements.

The British Red Cross logistics team regularly reports directly to the international directorate on performance against stock targets, through the weekly logistics status report and the international directorate’s quarterly reports (international dashboard report).

Every year, the logistics team suggests reviews to the British Red Cross’ stock offer in view of the data (see the British Red Cross stocks in IFRC’s OLPSCMs section above). The emergencies team is free to accept or refuse the proposed changes, based on their understanding of the future responses of the British Red Cross and on regional priorities.

It is important to understand the segregation between ownership and management of stock: logistics must seek approval from emergencies every time a stock movement is considered. For more details on budgeting for pre-positioned stock, see the British Red Cross management of stocks section.

In 2020, the British Red Cross current stock strategy and targets were as below:

| Item description | Kuala Lumpur | Dubai | Panama | Zimbabwe |

|---|---|---|---|---|

| Blanket cotton | 10,000 | |||

| Blanket light thermal | 1,500 | |||

| Blanket medium thermal | 20,000 | 15,000 | 3,500 | |

| Plastic bucket | 3,000 | 2,500 | ||

| Family tent | 500 | |||

| Hygiene kit | 2,000 | 1,000 | 750 | |

| Jerry can 10L | 8,000 | 4,000 | 1,500 | |

| Jerry can 20L | 3,500 | |||

| Kitchen set A | 6,000 | 3,000 | 750 | |

| Kitchen set B | - | |||

| Mosquito net - large | 11,000 | 5,000 | 1,500 | 3,000 |

| Plastic mat (sleeping mat) | 13,000 | |||

| Shelter toolkit | 4,000 | |||

| Tarps | 25,000 | 6,000 | 1,500 | 3,500 |

| WH tent | 2 | 1 | 1 | |

| Watsan kit 5 | - | |||

| Rapid latrines | - | |||

| Bbowl and ptrap | ||||

| Squat plates | - |

Available to download here.

Note: the logistics team share the updated stock levels with the entire international directorate on a weekly basis in the logistics status report. Current stock levels and latest stock movements are listed on the first pages of the report.

Where the OLPSCM’s storage capacity becomes insufficient, there is an option to store items in one of the UN Humanitarian Response Depot (UNHRD) warehouses. UNHRD maintains a network of strategically located hubs for pre-positioning relief items and humanitarian support equipment. It can provide storage free of charge in Ghana, Italy, UAE, Malaysia, Spain and Panama. It is also possible to source certain items from the UNHRD network. For more details, liaise with the UK-based logistics team.

Read the next section on Stock management principles here.

Related resources

Download useful tools and templates here

Download the full section here.

Assets require more tracking than regular items (see flowchart of definitions). When an asset is received, some of its details must be captured and periodically updated on an asset register. Maintenance services performed on assets must also be kept on file, in order to monitor the usage of the asset.

When assets are issued, the responsibility to maintain them lies with the person to whom they have been issued. When assets are in storage, they are under the responsibility of the asset manager.

Asset transfers must be recorded on asset transfer forms and the assets’ status must be kept updated on the asset register.

The asset register should be used as an asset report and shared with the project team at an agreed frequency (most commonly monthly), but also with donors when they request it and with the finance team when they require information about the value of assets.

Registering assets

When assets are received, an asset folder must be created and references captured on the asset register, so and can easily be traced back.

The asset manager is in charge of tracking the sequence of asset numbers, and of allocating the next available number to the newly received asset following an agreed numbering convention.

Examples of asset numbering conventions:

Name of + Country of use + Asset category + Acquisition year + Sequence number

BDRCS/BANGLADESH/FLEET/2019/22

Or more simply:

Name of NS + Sequence number

BDRCS/22

Note: any numbering convention is acceptable, but it must be used consistently.

The asset number must be captured on the GRN and tagged on the asset as soon as possible.

Make sure that the asset tags used are secure or engrave or paint the asset number on the asset (on generators, vehicles, etc). This becomes the asset’s identification number and must be unique to that asset.

The asset can then be recorded on the asset register, where more details will be listed, such as:

- asset number

- category

- description

- brand/make

- model

- serial number

- budget codes used to purchase the asset (project code), and donor code (where applicable)

- date of purchase

- purchase order reference

- purchase value

- current value (provided by finance)

- GRN reference

- maintenance plan (where relevant – how often does it need to be serviced?)

- person responsible (must match the most recent asset transfer form)

- location (current physical location or point of use)

- status (for example, OK, damaged, in repair, lost, broken or stolen).

All documents related to a single asset must be kept together in an asset file – this can be a plastic file, for example, with a cover sheet listing the documents on file and the date at which they were added.

Documents related to the maintenance, transfer, receipt, insurance, sale and donation of the asset must be kept in that file.

All asset files should be kept together in an asset management folder.

Note: when an asset is received as a donation from a partner, it must be allocated a new asset number and entered on the asset register as a new asset.

For guidance on asset value, refer to the Determining fair market value section of Asset disposal.

Asset responsiblity

Asset responsibility is allocated through an asset receipt form or asset transfer form (both have the same purpose, but the Red Cross Movement generally uses asset transfer forms). Every time the main user of an asset changes, an asset transfer form must be completed and kept on file, and the asset’s status must be updated on the asset register. When the asset transfer form is complete, the user of the asset assumes responsibility for it and their name must be recorded on the asset register as the current user.

When an asset is not allocated to any specific person, it is the responsibility of the asset manager and must be shown as such on the asset register. It is then the asset manager’s responsibility to ensure the asset is stored safely and securely while not in use and that the necessary maintenance services are performed.

The asset manager should have access to a storage space to hold the unallocated assets, which can be anything from a locked cupboard to a storage room. The assets should be stored by category, with their asset tags or markings easy to read while in storage.

Some assets, such as buildings and vehicles, require insurance. Assets must be insured locally unless they are purchased in an organisation that holds global insurance for their assets (always ask your regional logistics coordinator to confirm the status of partners’ asset insurance).

Unless it is a legal or donor requirement, if the insurance cost is higher than the replacement cost (and if this can be shown through quotes), taking out an insurance policy is not mandatory.

Owned buildings, property or land must be captured on the asset register but rented properties may or may not have to be, depending on the duration and financial management of the lease (depreciation can sometimes be applied to long-term rental agreements). Refer to your finance team and/or to the UK-based logistics coordinators to confirm whether a leased building or property should be on the asset register.

Note: some donors may require some categories of assets to be insured. In this case, insurance costs should be covered by the donor requesting the insurance.

Asset checks

Asset checks should be conducted regularly. It is good practice to have five per cent of the asset register, or a minimum of ten assets (whichever is highest) checked against the asset register by finance and logistics staff in each of the country offices on a monthly basis, using the asset spot check form.

All differences must be investigated and reported on the asset spot check form by the staff who conducted the spot check (finance and logistics) and signed:

Locally: by the asset manager’s line manager, programme manager or country manager.

HQ level: by the head of logistics.

The asset spot check form must be signed within a month of being raised, asset checks are required by default, unless otherwise specified in the . The asset spot check form does not need HQ sign-off if it does not identify discrepancies.

A full physical check of all assets must be completed by finance and logistics staff on an annual basis, preferably just before the end of the financial year. All differences must be investigated and reviewed per the same process as for asset spot checks. Following the annual asset check, the asset register must be updated, and the approved investigation report must be attached to the next dissemination of the asset register.

All asset check forms must be kept in the asset management file. The asset manager must keep track of the assets that have been checked during the monthly spot checks to ensure that different assets are checked each month, on a rolling basis.

Following the monthly spot check, the asset register must be updated and the spot check form should be attached to the next dissemination of the asset register.

Reporting on assets

Most donors require regular information about assets purchased with funds they have provided. The details in the asset register should cover all the information they require, but it is good practice to agree beforehand on the information that will be shared.

Whenever new partnerships are designed, it is advisable that the future grant recipient shares their version of an asset register with the donor, to ensure that the level of information is sufficient.

Assets that have not been used for over a year should be reported to senior management by the asset manager, to discuss potentially disposing of them. See the Asset disposal section for more details.

Asset depreciation

The value of assets owned by an organisation sits on its balance sheet. Keeping the balance sheet updated is usually the responsibility of the finance team, but the information required for the process is often shared between logistics and finance. Communication between teams is critical when it comes to recording the right assets at the right value.

In the British Red Cross, see the “Guidance on accounting for fixed assets” (available on Redroom) for information about capitalising assets. Note that in , each team is responsible for their own assets and must maintain an asset register to be shared with the finance team when required (for the end-of-year report for example).

At British Red Cross, assets with a value above £1,000 and with a useful life of more than one year must be capitalised and depreciated. Further details can be found in the policy. Finance should be consulted to understand which assets incur depreciation (not all of them will).

An asset will typically be allocated a life cycle of x years, and its value will decrease by the same amount every year for x years. At the end of x-year life cycle, the asset’s value will be 0. Those 0-value assets still need to be managed as all other assets, and their status must be updated on the asset register.

It is not the responsibility of logistics to apply depreciation to the assets. The asset manager must make sure the depreciated values are computed and shared in due time to report on the total value of assets.

Asset maintenance

Assets that require regular maintenance or inspection services typically include:

- all fleet, including generators and mechanical handling devices (i.e. forklifts)

- buildings, whether owned or rented

- medical equipment

- IT and comms equipment

- some household items.

Regular maintenance

Regular maintenance should be incorporated into the usage cycle of assets. For example, it should be reflected in the fleet plan and the drivers’ allocation plan.

A maintenance planner should be used to visualise all completed, ongoing and upcoming maintenance, and covering all the assets that require maintenance. A maintenance planner is included as a tab in the asset register template. It is important to consider legal requirements that apply to categories of assets: for example, an annual vehicle inspection is required in certain countries, with the renewal of the roadworthiness certificate.

See the Fleet chapter for more details on fleet maintenance and maintenance planning.

See the British Red Cross portable appliances technical guide for details of the maintenance procedures to follow regarding British Red Cross-owned electrical assets in the UK. This guide should inform the maintenance planner for the UK logistics team.

See guideline for maintenance of British Red Cross-owned vehicles in the UK.

Note: Most of the maintenance requirements for buildings in the UK will be covered by British Red Cross’ maintenance service provider. To request a maintenance service, contact , so they can schedule it via the facilities management contractor.

Unplanned maintenance

Unplanned maintenance needs must be identified as such and avoided as far as possible. When they do occur, a maintenance request must be authorised by the asset manager, and the associated costs should be recharged to the budget code of the user requesting the maintenance.

Cost of maintenance

The cost of maintenance associated with an asset should be monitored, with copies of invoices for maintenance services included in the individual asset files kept in the asset management folder.

Looking at the cumulative value of maintenance costs associated to a specific asset can support a decision to dispose of an asset, replace it or to switch to renting rather than owning similar items.

For vehicles, generators and some electrical/medical equipment, maintenance should also be captured in the logbook.

Read the next section on Asset donations here.

Related resources

Download useful tools and templates here

Download the full section here.

Consumables/office supplies

Consumables don’t need to be taken as stock or assets, as their value is usually low. These include cleaning materials, stationery, lightbulbs, and other replacement items.

View and download a diagram illustrating how such items are managed here.

Equipment

Items that are worth less than £1,000, not powered by electricity, do not incur maintenance costs, have a useful life of less than 3 years, and are not defined as assets by the donor who funded their purchase, are classified as equipment and should be tracked on a property register.

Furniture, unless items worth more than £1,000 should be included on the property register rather than on the asset register.

Stocks

For the management of stocks, refer to the Warehousing chapter.

Read the next section on Procuring assets here.

Related resources

Download useful tools and templates here

Download the full section here.

Assets

Assets, stock, equipment: definitions

Learn more in the Definition of an asset, Categories of assets and Items not to be managed as assets sections.

Asset procurement

Learn more in the Procuring assets section.

Asset management

Learn more in the Registering, tracking and reporting assets, and filing section

Asset donations

Learn more in the Asset donations section.

Asset disposal plans

Learn more in the Asset disposal section.

Assets ownership

Learn more in the Note on asset management and partnerships section.

Download the whole Assets chapter here.

Note: In the following sections, vehicles can be cars, trucks, planes, or ships. Where variations from the process occur, they are detailed at each step.

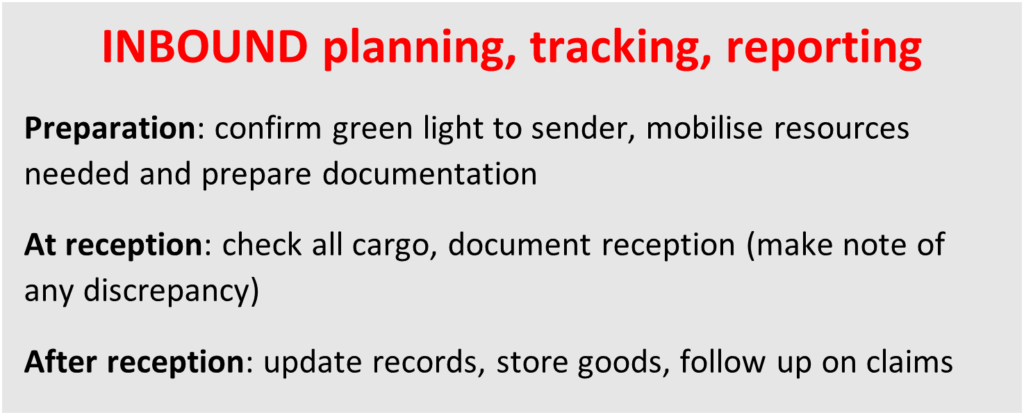

When planning inbound movements of freight (i.e. receiving a consignment):

Preparing for reception

The sender must always inform the consignee ahead of shipping goods, sharing as much information as possible on the shipment before the vehicles leave for delivery.

Information to share ahead of shipping:

- expected arrival date and time

- goods transported: a draft packing list or reference to orders (requisition), estimated weights and volumes

- vehicle details: registration, driver/pilot details and route. For sea shipments, this will be vessel route and shipping line

- special requirements: cold chain, dangerous goods, bulky equipment, etc.

- details of vehicles: schedule, number of trips and prioritisation.

The receiver should confirm their capacity to handle the inbound shipment and make necessary arrangements.

Arrange your reception area to ensure the full consignment can be temporarily stored before being moved into the bulk storage area – if necessary, make temporary adjustments to the warehouse layout to accommodate the incoming consignment.

Communicate temporary changes to the layout to the warehouse team.

To prepare for reception:

- plan for space to offload

- plan for documentation to track offloading process – ensure a detailed packing list is available

- plan for available manpower to offload

- plan for cold chain capacity if needed

- re-schedule planned orders with the warehouse team and end users

- prepare labels for storage

- rent or procure handling equipment if necessary

- prioritise processing order with end users.

Information to share after shipping:

- container seal number where relevant

- expected ETA

- copy of final transport document (waybill, bill of lading, air waybill, CMR where relevant)

- exact contents of consignment: final packing list, weights & dimensions, specific handling requirements and markings

- contact details of driver/pilot and rental company (if relevant).

The captain of a vessel can usually not be contacted directly, but vessels can be tracked by a bill of lading.

Note: where the shipper of the goods is the supplier of the same goods, the same details must be obtained from them.

| Sharing shipment details | Provided by | |

|---|---|---|

| Responsible | Shipper | Receiver |

| Accountable | Receiver | Receiver |

| Consulted | Receiver/requestor | Requestor |

| Informed | Requestor | Shipper |

At the time of reception

| When to count containers | When to count pallets | When to count boxes | When to count boxes' contents |

|

|---|---|---|---|---|

| Air | N/A | At airport if palletised | At airport if unpalletised At delivery place if palletised | At delivery place |

| Sea | At port | At port if possible At delivery place otherwise | At port if possible and unpalletised At delivery place if palletised | At delivery place |

| Road | At delivery place if relevant | At delivery place if relevant | At delivery place | At delivery place |

| Rail | At delivery place if relevant | At delivery place if relevant | At delivery place if relevant | At delivery place |

Available to download here.

Note: counting the contents of sea freight containers (pallets, boxes, loose goods, etc) can often not be done at the port and has to be done either at the final delivery place or at the freight forwarders/clearing agent’s premises.

Road consignments will usually be delivered straight to the delivery point. At the time of offloading, make sure every unit (pallet or box) is accounted for, and store them separately until the entire content of the boxes has been reviewed against the shipping documents accompanying the truck. Where a transhipment is needed, all pallets and boxes must be accounted for during the transhipment.

At time of reception:

- Check that all documents are attached to the consignment: commercial invoice, gift certificate, packing list, waybill, bill of lading, air waybill or CMR sheet (where applicable) and any customs clearance certificate (including tax waiver documents where applicable).

- Check that container seals are in good condition.

- Check the condition of each box/pallet as it is offloaded and check for labels.

- Confirm number of boxes matches the consignment documentation in each vehicle/container.

- Check and inspect the contents of each box to confirm exact quantities received against the packing list attached to the consignment.

Record any discrepancy and reconcile only once all boxes have been inspected (sometimes all ordered goods are in the consignment, but the packing lists are not accurately broken down per packaging unit). - If receiving a cold chain consignment, read the temperature-monitoring devices attached to the consignment, to confirm cold chain has been maintained throughout the transport process.

Offloading trucks

If available, use loading docks or platforms. Otherwise, position the truck on level, solid ground, as close as you can to where the goods must go to.

Allow enough space for movement around the truck, especially if you are using a forklift truck or hand pallet truck.

If you have inbound trucks and outbound trucks available simultaneously, consider whether it is worth trans-shipping directly from one truck to the other (as long as you can control the process and ensure accurate counting is done).

If handling equipment is not available, do not throw unidentified goods from a truck but hand them down carefully.

If goods must be manually handled because there is no handling equipment, use a chain of people (with one person in charge). The chain must have enough people for each person not to have to ‘walk’ more than one step. The people should be placed facing alternately along the chain to avoid unnecessary ‘twisting’.

View an example diagram of correct offloading of trucks here.

Avoid handling goods more times than you must by only putting them down where they have to go, in the stack they have to go in (see the Storage options section of Setting up a warehouse for more information on stacking). If the person you are handing the goods to is not ready, call the chain to stop.

Always maintain height if you can. Do not put goods on the floor if they must be lifted up again.

Make sure someone who is not handling the goods is counting as the goods are moved. That person should keep a tally (marking off per layer removed or built, for example), in case they get interrupted and cannot remember where they had counted to.

A check count should be done when each stack is created.

When all goods are offloaded, cross-check offloaded quantities against shipping documents and make note of any discrepancy.

Remember to take breaks when needed during offloading and make sure drinking water is readily available.

Documenting the reception

For details on how to receive goods in a warehouse, see the Receiving stock, Document the reception, Receiving stock for the British Red Cross (in UK or at Regional Logistics Units) and Releasing stock sections of the Warehousing chapter.

After reception of the goods

Record all received quantities on the appropriate stock cards and bin cards, referring to the GRN/ as appropriate.

Transfer the goods from the reception area to the main storage area as soon as possible.

In case of any claims, follow up on resolution options with the sender/transporter, agreeing on corrective measures to be put in place for future shipments where relevant.

Log the shipment in a shipment tracker, with complete details of the consignment – this will be used in the activity reporting process.

Inform the requestor and sender of completed delivery: share a copy of the GRN. Detail any measures being taken to address claims and raise (where applicable).

For more details on the reception of international cargo, refer to the Warehousing chapter.

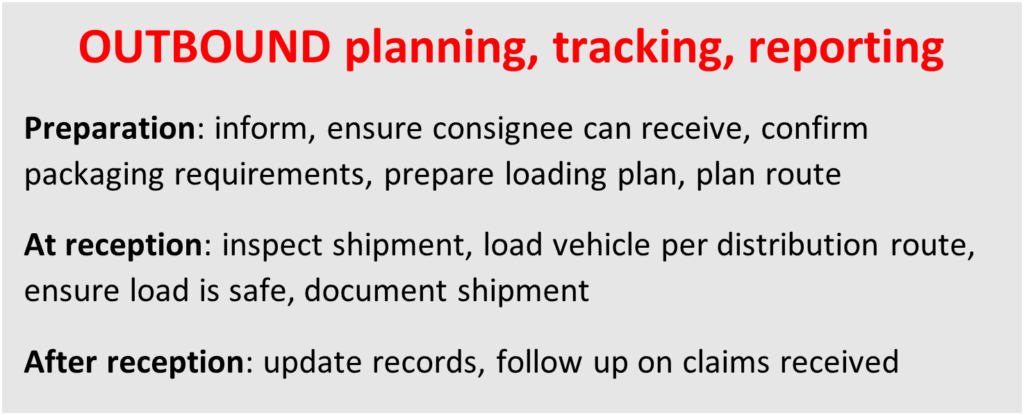

Preparing outbound shipments

When planning outbound movements of freight (i.e. shipping a consignment):

The sender must always inform consignee ahead of shipping goods, sharing as much information as possible on the shipment before the vehicles leave for delivery.

Information to share ahead of shipping:

- expected arrival date and time

- special requirements: cold chain, dangerous goods, bulky equipment, etc.

- goods transported: a draft packing list or reference to orders (requisition), estimated weights and volumes

- details of vehicles: schedule, number of trips and prioritisation

- vehicle details: registration, driver/pilot details and route. For sea shipments, this will be vessel route and shipping line.

Move the goods to be shipped to a designated dispatch area. The dispatch area can be temporarily modified as necessary, but make sure the warehouse team is informed of any changes.

Inspect the goods to be shipped: are all packaging units in good condition? Ensure cartons/pallets are stripped of any markings that could lead to confusion.

What are the packaging/labelling requirements? Be sure to ask the transporter and the consignee about any specific requirement they may have. Shipping instructions will also be helpful to find information about such requirements.

What will be the route of the vehicle, and the shipping mode? This will impact the loading plan and must be agreed with the transporter as early as possible. When sending sea shipments, control over the loading plan will be with the shipping line.

Where temperature control is required, cold chain materials (thermometer, temperature tracking devices, cool boxes, icepacks, etc.) must be made available.

Raise a final packing list with all details of the consignment. In the Red Cross movement, the waybill is often used as a packing list however it is sometimes easier to use both documents separately (for very large consignments for example).

Use a load optimisation tool to determine best transport options (this only works for road shipments).

Place the request for the necessary vehicles well in advance (as per the terms of the service-level agreement defined in the contract, where relevant), ensuring that you receive driver/pilot details and a vehicle registration certificate before the shipping date.

Ensure the necessary manpower and loading equipment will be available for loading the vehicles.

When using shipping containers, make sure the use of the containers is optimised and suggest changes in quantities where relevant (e.g., when five per cent of the order does not fit into a single container, the consignee might be willing to postpone the delivery to save the cost of the extra container).

Based on the number of packaging units shipped, prepare a loading sheet to give to the loaders, so they can track the progress of the loading process.

Where multiple vehicles are transporting multiple items, agree in advance the load composition (i.e. whether each vehicle holds a combination of all the items or only one type of item).

Loading trucks

- If available, use loading docks or platforms. Otherwise, position the truck on level, solid ground as close as you can to where the goods have to go to or come from.

- Allow enough space for movement around the truck, especially if you are using a forklift or hand pallet truck.

- If handling equipment is not available, do not throw unidentified goods from a truck but hand them down carefully.

- When loading trucks, always stack goods starting at the front of the truck and work towards the back.

- Always place the heaviest goods on the floor of the vehicle.

- Rules about stacking also apply on a truck (see the Storage options section of Setting up a warehouse).

- If you are loading a truck for distribution, lay the goods along the length of the vehicle, so that complete sets of whatever is being delivered can be distributed off the back of the truck (unless the truck has an open top or can be easily accessed from the sides, like a ‘wing’ truck).

View an example diagram of a truck loaded for direct distribution here.

At the time of dispatching

- Hand out loading sheets to loaders and retrieve them after the vehicle is loaded.

The loading sheet should simply list all the parcels to be loaded, and one loader should monitor loading progress by ticking the parcels off as they are loaded on the truck. - Confirm the route of the vehicle.

- Raise a waybill, detailing the quantity of units (pallets, sacks, boxes) loaded, weight and volume per unit and total weight and volume of the consignment.

Alternatively, waybills can detail the total quantity, weight and volume per item included in the consignment (in particular when goods are sent unpalletized or loose). - Place seals on containers where necessary.

- Ensure load is safe (with no risk of spillage or cross-contamination, etc) and securely fastened inside the vehicle – straps can be used, or blankets can be used to secure a load on a half-empty truck, for example.

- When sending a cold chain shipment, double check the cold chain plan and ensure that clear instructions are given to the transporter.

The shipper and the driver must sign the waybill and one copy must stay at the origin.

Documenting the consignment

- The transporter will leave with three copies of the waybill.

- Certain countries or regions will require the shipper to obtain a permit to access certain areas – make sure you request such permits from the relevant authorities.

- Keep a copy of the outbound waybill, to be reconciled with the returned signed copy after reception is confirmed by the receiver.

- Where delivery is planned directly at a usage point (a distribution point where no stocks are managed, for example), a GRN will have to be raised.

The delivery will not always happen at a warehouse, so a logistician should go to the delivery site and conduct the check of the delivered items and raise the GRN with the requestor of the goods.

Where goods are missing or damaged, the GRN will be returned with a filled-out claims form.

It is safer to ensure that drivers/pilots are issued with a mission order, confirming that they are moving humanitarian goods. A standard mission order should be available in each delegation/mission/project.

After dispatch

- Log the shipment in a shipment tracker, with details of the consignment. This will be used in the activity reporting process.

- Update your stock cards and bin cards (where relevant).

- Inform the receiver of revised expected time of arrival and confirm the transporter’s contact details.

- After receiving the returned signed copy of the waybill and GRN, where claims have been raised, make sure they are addressed, and that a corrective plan is in place to avoid future disruptions.

Read the next section on Shipping instructions here.

Related resources

Download useful tools and templates

Download full section here.

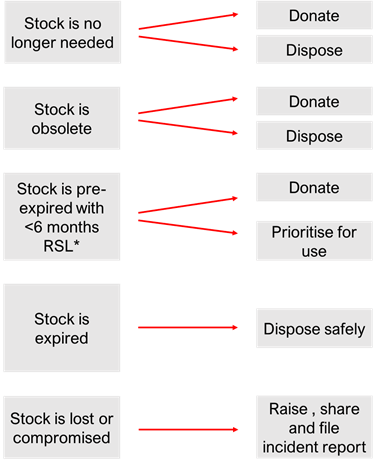

Stock that is not used by its owner should be donated or disposed of, depending on the context and on the quality of the items. In either case, the stock movement must be recorded like any other, and the value of stock transferred must come off the inventory. Stocks owned by the British Red Cross are written off, i.e. taken off the logistics balance sheet.

The British Red Cross has determined the following priority order, through which asset/inventory disposal must be executed:

- Donation to

- Donation to Movement

- Donation to local partner

- Donation to another humanitarian actor

- Sale

- Destruction

Donation to staff is strictly prohibited, though staff and volunteers are permitted to bid on items which are on sale.

There are various reasons to write stock off:

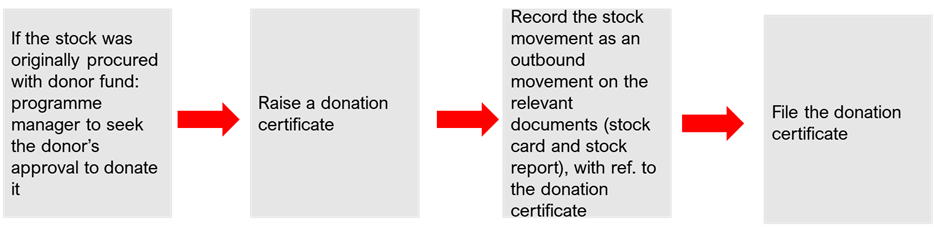

Donating stock

Before donating stock, make sure that:

The prospective receiver wants the items -> ask: “Do you want the items?”

The prospective receiver can safely use the items -> ask: “Can you provide guarantees that you have the means to use and control the items safely?”

A donation can be made to a partner organisation or to a separate project within the same organisation, though it is then more of a transfer.

In all cases, the process to follow is the same:

The donation certificate:

- Must include at least an estimate of the total value of the donated items.

- Must be approved as per the approval matrix: the higher the value of the items donated, the more senior the approver – follow guidance in the Registering assets section of the Assets chapter.

- Must be signed by the stock owner (programme manager) and the receiving organisation/partner.

Finance must be informed of the value of the donated or transferred stock so they can reallocate the values accordingly. Ideally, the total value of donated stock must be communicated to finance on at least a yearly basis, through a donation report.

When receiving donated stock, the donating partner or programme must raise the donation certificate, and the receiver of the donation must record the quantity as an inbound stock movement. The total value of received stock must be reported on a similar basis as the donated stock. See stock donation tracker format. The format must be used for recording asset and stock donations – see the Assets chapter for more details on asset donations.

Disposing of stock

Disposing of stock means destroying it and should be a last resort. Where stock is disposed of, this must be done in a safe and legally compliant way.

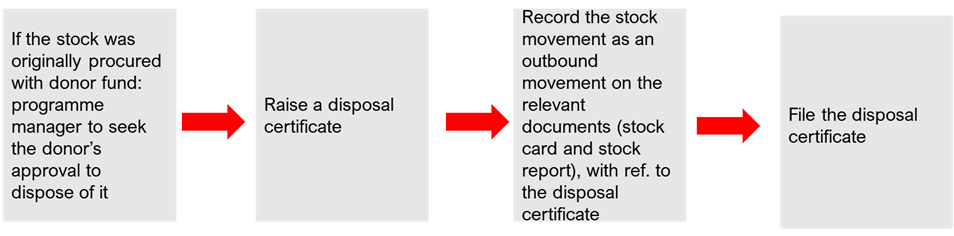

The process to follow is:

The disposal certificate must:

- include at least an estimate of the total value of the disposed items

- be approved as per the approval matrix: the higher the value of the items disposed of, the more senior the approver – follow guidance in the Registering assets section of the Assets chapter

- be signed by the stock owner (programme manager) and the receiving organisation/partner.

Finance must be informed of the value of the disposed stocks, so they can write its value off accordingly. Ideally, the total value of disposed stock must be communicated to finance on at least a yearly basis, through a donation report.

When disposing of food items, medical supplies, dangerous goods or chemicals, it is recommended to liaise with the appropriate local authorities to understand the rules that apply. Where destruction is required, it must be documented by a destruction certificate, signed by the disposing of the stock and the authority overseeing the destruction. Note that authorities usually charge a fee for destruction.

If stock is returned to the UK damaged or if items in stock in the UK or in any of the global warehouses expire (e.g., water purification drops, first aid kit), they must be written off in a stock write-off form, in which the logistics officer must justify the reasons for the write-off and propose options for dealing with the stock which could include:

- Donating items (e.g., to shops or UK operations). If items or equipment are in good condition and have resale potential, contact the eBay manager in retail who will consider them for posting on eBay.

- Recycling or disposing items. Radios, satellite phones and electronics need to be disposed of properly and the TA should contact IT or a supplier to dispose of items properly.

The logistics officer documents different options, stating the preferred option in the recommendation section and gets this signed off by the head of logistics.

When the form is signed, the logistics officer gets this agreed or written off by finance and actions the agreed outcome.

Note: additional funds will need to be requested for higher value asset write-offs, as they are deducted from logistics management’s budget.

Recording a stock loss or theft

An incident report must be completed when stock is stolen or lost to damage, destruction or bad management, where the total value of the loss is above £100.

The incident report must be raised by the warehouse staff in charge of the stock, with proposed follow-up actions reviewed by the Logistics delegate and approved by the logistics coordinator. The incident report must specify the estimated value of the total loss.

Where the incident report is raised to report on stocks held in , Bulwick or in the ’s , the incident report must be prepared by the logistics officer, reviewed by the logistics manager and approved by head of logistics and international finance. See SOPs for more details on these procedures.

The quantities declared as lost must be reported on the stock card and report, with reference to the incident report.

Read the next section on Health and safety in the warehouse here.

Related resources

Download useful tools and templates

Download the full section here.

Inventories (stock takes) are helpful to:

- know what is in stock, by quantity, value and quality

- agree corrective actions in case of discrepancies or poor quality of stock

- update reporting tools.

Stock takes should follow two separate patterns:

Cycle counting

It is good practice to have five per cent of stock, or a minimum of ten stock cards, checked each month.

This process should be led by the warehouse manager or team, with a stock spot check report prepared and shared with the finance team member in charge of stock and balances, and with the stock owner.

All differences must be recorded on the stock spot check report and investigated and explained within one month or before the next stock spot check takes place. This should be done by the warehouse manager, under the supervision of the logistics delegate.

All boxes/pallets that are counted can be sealed and strapped after the finance and programme business partner have accepted the spot check, so they don’t need to be counted again during the 100 per cent stock takes.

Cycle counting can also be done on a predetermined cyclical schedule. Effective cycle counting requires the counting of a pre-set number of items every workday and should result in the counting of all warehouse stock twice a month (refer to the below section on cycle counting procedure).

Cycle counting procedure

The number of stock cards determines the frequency of the cycle count.

To calculate the number of items to be counted daily in order to permit a complete count of all warehouse stock twice during the month, multiply the number of stock cards by two and divide the result by the number of workdays in the month.

For example:

30 stock cards in warehouse: 30 x 2 = 60

20 workdays in month: 60/20 = 3

In this example, the items listed on three stock cards are to be counted each day.

A schedule for conducting cycle counts is then established and integrated into the daily or weekly routine. Bin cards, stock cards and the documents certifying receipt or dispatch (waybills, ) of the supplies being controlled are verified.

The latest global stock report is crosschecked against the stock cards. A physical count is performed for the selected items and crosschecked with the stock cards and bin cards. When variances are found, the cause (e.g., count error, recording error, unrecorded dispatch, theft) is identified and appropriate corrective actions are taken.

100 per cent stock audit

It is mandatory to conduct at least one 100 per cent stock take each year.

It is good practice to conduct two 100 per cent stock takes per calendar year.

All counted quantities should be reported on a stock take report, with all discrepancies recorded and investigated, and the report approved by relevant authority (usually head of logistics or head of delegation) and shared with all stock owners and the head of logistics or delegation within one month of the stock take.

Before a stock take:

| Stock spot check (monthly) | 100% stock check (twice yearly) |

|

|---|---|---|

| -90 days | Invite finance and programme business partners to join the count Inform all stakeholders about service interruption |

|

| -30 days | Inform stock owner of items to be counted and the date of the stock spot check Ask for no movement of these items on selected date (provide 'last order' deadline) | Confirm counters' attendance |

| -15 days | Ensure all orders for items included in the next spot check are in and ready for preparation - they must be delivered before the stock take date | Remind stock owners of warehouse closure Prepare stock take brief Prepare the counting document |

| -5 days | Prepare the counting document | Update stock report with latest stock movements Prepare stationary items needed for stock take |

| -1 day | Update stock report with latest stock movements of counted items | Ensure all units of same items are stored together (group same items together) |

Available to download here.

During a stock take:

| Stock spot check (monthly) | 100% stock check (twice yearly) |

|---|---|

| Locate items to be counted | Ensure no order preparation is pending Update stock reports with latest stock movements if necessary |

| Record a physical count on the stock take sheet (theoretical stock not included) | Brief counters on their role Allocate counting responsibilities |

| Mark up all counted boxes (colour code or date-stamp) | Distribute counting sheets Theoretical stock should not be visible on stock take sheet Blank lines should be added to record additional items if needed |

| Reconcile physical count with stock cards Highlight and investigate discrepancies Use GRNs, donation certificates, waybills and stock request forms | Ensure counters open every box they are asked to count unless contents of a box have been counted during a stock spot check |

| Fill out a stock spot check report and submit to warehouse manager and stock owner | Ensure all counting sheets are handed to warehouse manager and signed off by counters |

Available to download here.

After a stock take

| Stock spot check (monthly) | 100% stock check (twice yearly) |

|

|---|---|---|

| Same day | Record physical count on stock card (report in red or other identifiable format) | Invite finance and programme business partners to join the count Inform all stakeholders about service interruption |

| Within 1 week | Update stock report with confirmed physical quantities Seal and strap counted boxes/pallets Agree required corrective actions and record in stock spot check report File stock spot check report | Reconcile physical count with stock cards Highlight and investigate discrepancies Use GRNs, donation certificates, waybills and stock request forms |

| Within 2 weeks | Agree required corrective actions and record in stock take report Prepare stock take report, submit to head of logistics and stock owners File stock take report |

Available to download here.

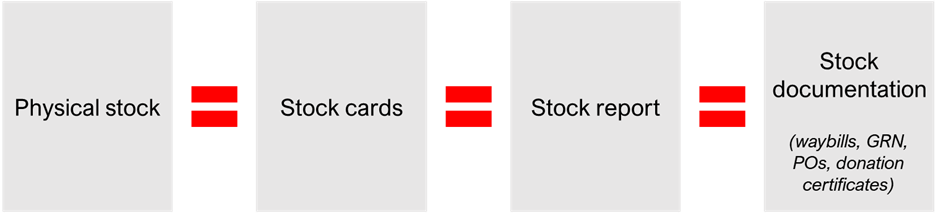

Note: stock audits can be conducted by internal or external auditors, outside of scheduled stock takes. The warehouse manager will have to produce the necessary documents to conduct a four-way match between physical stock, stock cards, stock report and /waybill/donation certificates/.

Stock reporting

The stock report

The summary of all stock cards is the stock report or stock movement report, which is used for reporting and overall stock management.

The stock report should be in a simple format, capturing the opening balance, quantities received (split between purchases and donations) or issued (split between requests, losses, donations or disposal), and closing balance for each item in stock.

Stock reports are usually updated on a monthly basis and shared with stock owners as a snapshot of the available quantities in the warehouse, though finance and -based logistics coordinators may also request to receive them. In emergency operations, this report can be required to be shared on a weekly or a daily basis.

In addition to the above, the periodic stock report should ideally highlight:

- the 20 per cent fastest-moving goods in the warehouse

- the 20 per cent slowest-moving goods in the warehouse

- where items are perishable, those quantities expiring within the next six an three months must be highlighted and actions to avoid wastage agreed.

Annexes to the stock report

- The monthly warehouse checklist must be completed and attached to the stock report.

- Quarantined items must either be reported against separately or visually identifiable in the report, with the reason for placing the items in quarantine clearly.

- A warehouse dashboard can be put together and shared with stock owners and other clients to give a measure of the activity level in the warehouse and inform of any upcoming changes (such as deep cleans, training events or stock counts).

- The value of any stock donations (received or issued) must be known by the warehouse team and included in the report for Finance to record. If requested, donation certificates must be produced.

- Ideally, the total value of stock losses (due to expiry, theft or damage) must be known and included in the report for finance to record. If requested, disposal or loss certificates must be produced.

Always consult with the stock owner to be informed of any specific donor requirements. Donors will usually want to know the value and content of the stock balance at the end of a project they fund.

Read the next section on disposing of and writing off stock here.

Related resources

Download useful tools and templates

Download the full section here.

Remember to apply the First In, First Out rule: all supplies should, in principle, leave the warehouse in the order in which they arrived. The exception is the First Expired, First Out rule; items with expiry dates must be distributed according to their expiry date. Additionally, damaged, infested or damp goods that are still fit for human consumption must be repackaged and distributed before older stocks and without delay, to avoid further loss.

Remember that management of the stock is delegated to the warehouse manager or Logistics delegate in charge of the warehouse, while ownership of the stock remains with the budget holder, generally the programme manager. Therefore, logistics must guarantee the traceability of stock movement and report to the stock owner on the same.

To support this, systems must be implemented to release stock, deliver items safely and document all stock requests processed by the warehouse team.

Prior to releasing stock from the warehouse:

Stock release must be authorised by the stock owner.

Generally, requisition forms are used as stock request forms to document approval of the stock release, by ticking the “request for stock issue” box. Where this option is not available, a separate stock release form should be developed.

The stock request form should be filled out by the requestor, reviewed by the requestor’s supervisor and approved by the stock owner. The warehouse team should also sign the stock request to signify their acceptance of the order preparation task. The warehouse team is responsible for keeping the approved stock request forms on file and must be able to give access to the records during an audit.

A packing list must be raised and communicated to both the requestor and the consignee of the stock (if different). It must provide a breakdown of the consignment per packaging unit (box, sack, barrel, etc), with the weights and dimensions of each container included in the consignment.

The packing list must be prepared by the warehouse staff in charge of order preparation and reviewed by the warehouse manager before the consignment leaves the warehouse. A separate packing list must be issued for each order. Several orders can be loaded onto the same vehicle, so the driver of a vehicle might be given several packing lists.

Within the Movement, waybills are often used as packing lists, in which case there is no need to include a separate packing list.

| Requisition (stock request form) | Packing list | Waybill | |

|---|---|---|---|

| Prepared by | Requestor | Warehouse staff (storekeeper) | Warehouse staff (dispatcher) |

| Authorised by | Stock owner (budget holder) | Warehouse manager | Warehouse manager |

| Received by | Warehouse staff | Transporter Consignee | Transporter Consignee |

| Signatory | Warehouse staff | Storekeeper Warehouse manager | Warehouse manager Transporter Consignee |

| Contents | Details of items requested and quantity (use item codes if possible) Requested delivery date and place | Detailed contents per packaging unit (box, container, pallet...) Weight and volume per packaging unit | Total number of packaging units per consignment Total weight and volume Sender and consignee details Transporter details |

| Reference to | Programme code (budget, activity) | Requisition(s) | Packing list(s) |

| Copies | Requestor Warehouse | Warehouse Receiver | Warehouse (x2) Receiver Transporter |

Available to download here.

A waybill must be raised in four copies by the warehouse staff coordinating the shipping of the consignment.

It must outline the number of boxes/ pallets /containers making up the consignment and refer to the orders and/or that have been loaded onto the vehicle – either use references or packing list references, noted on the waybill.

The total number of containers and the weight and volume of the consignment for each individual order loaded onto the vehicle must be noted on the waybill.

How to prepare a consignment

The careful preparation of a consignment will avoid losses, claims and discrepancies, and mitigate the risks involved in delivering it to its consignee.

Step-by-step order preparation:

- Pick the items to be shipped and move them to the dispatch area.

- Group items into containers or onto pallets (having checked container size requirements with the consignee).

Remember to keep empty boxes/containers/pallets in the warehouse for re-packaging where required. - Split the consignment by item type – refer to the list of requirements for each item and document any dangerous goods as required.

- Count the total number of containers in the entire consignment.

- Print labels for each container, ensuring a is noted on the label if applicable.

- Safely close all containers, shrink-wrap and strap pallets.

- Stick labels to containers/pallets.

- Weigh and measure containers individually.

- Report consignment details on a packing list.

- Obtain packing list sign-off.

- Raise waybill for the consignee.

- Arrange or order transport services.

- Prepare vehicle loading plan as per agreed vehicle specifications (including box list).

- Load vehicle (ticking off boxes/pallets on the list as they are loaded) and hand documentation to the driver.

- Share the packing list, waybill and driver contact details with consignee to inform them of incoming shipment.

For details on shipping goods, see the Transport chapter.

Read the next section on Stock takes and reconciliation here.

Related resources

Download useful tools and templates

Download the full section here.

As detailed in their stock pre-positioning strategy, the currently holds stock in a number of different locations using Regional Logistics Units (RLUs). The IFRC also allows to use warehouses they run to pre-position stocks (see the stock Stock positioning section of Definitions and concepts).

British Red Cross stores items in these IFRC-run Non-Food Items (NFI) warehouses to respond to multi-lateral responses and for use within British Red Cross programmes and partnerships.

Stocks are also sometimes loaned to other . As part of this pre-positioning mechanism, and based on an annually reviewed agreement, the BRC currently holds stock in the following places, managed by the IFRC:

- Panama (Americas region)

- Kuala Lumpur (Asia region)

- Dubai (Middle East and North Africa region)

- Zimbabwe (East and Southern Africa region).

Each warehouse is managed by IFRC staff and follows IFRC standard operating procedures for its management, layout, access, staffing and procedures.

For more details about the procedures that apply to the maintenance, replenishment and deployment of the stock held in the RLUs, refer to the RLU SOP and to the RLU chapter of this manual.

Read the next section on Releasing stock here.

Related resources

Download useful tools and templates