Assets require more tracking than regular items (see flowchart of definitions). When an asset is received, some of its details must be captured and periodically updated on an asset register. Maintenance services performed on assets must also be kept on file, in order to monitor the usage of the asset.

When assets are issued, the responsibility to maintain them lies with the person to whom they have been issued. When assets are in storage, they are under the responsibility of the asset manager.

Asset transfers must be recorded on asset transfer forms and the assets’ status must be kept updated on the asset register.

The asset register should be used as an asset report and shared with the project team at an agreed frequency (most commonly monthly), but also with donors when they request it and with the finance team when they require information about the value of assets.

Registering assets

When assets are received, an asset folder must be created and references captured on the asset register, so and can easily be traced back.

The asset manager is in charge of tracking the sequence of asset numbers, and of allocating the next available number to the newly received asset following an agreed numbering convention.

Examples of asset numbering conventions:

Name of + Country of use + Asset category + Acquisition year + Sequence number

BDRCS/BANGLADESH/FLEET/2019/22

Or more simply:

Name of NS + Sequence number

BDRCS/22

Note: any numbering convention is acceptable, but it must be used consistently.

The asset number must be captured on the GRN and tagged on the asset as soon as possible.

Make sure that the asset tags used are secure or engrave or paint the asset number on the asset (on generators, vehicles, etc). This becomes the asset’s identification number and must be unique to that asset.

The asset can then be recorded on the asset register, where more details will be listed, such as:

- asset number

- category

- description

- brand/make

- model

- serial number

- budget codes used to purchase the asset (project code), and donor code (where applicable)

- date of purchase

- purchase order reference

- purchase value

- current value (provided by finance)

- GRN reference

- maintenance plan (where relevant – how often does it need to be serviced?)

- person responsible (must match the most recent asset transfer form)

- location (current physical location or point of use)

- status (for example, OK, damaged, in repair, lost, broken or stolen).

All documents related to a single asset must be kept together in an asset file – this can be a plastic file, for example, with a cover sheet listing the documents on file and the date at which they were added.

Documents related to the maintenance, transfer, receipt, insurance, sale and donation of the asset must be kept in that file.

All asset files should be kept together in an asset management folder.

Note: when an asset is received as a donation from a partner, it must be allocated a new asset number and entered on the asset register as a new asset.

For guidance on asset value, refer to the Determining fair market value section of Asset disposal.

Asset responsiblity

Asset responsibility is allocated through an asset receipt form or asset transfer form (both have the same purpose, but the Red Cross Movement generally uses asset transfer forms). Every time the main user of an asset changes, an asset transfer form must be completed and kept on file, and the asset’s status must be updated on the asset register. When the asset transfer form is complete, the user of the asset assumes responsibility for it and their name must be recorded on the asset register as the current user.

When an asset is not allocated to any specific person, it is the responsibility of the asset manager and must be shown as such on the asset register. It is then the asset manager’s responsibility to ensure the asset is stored safely and securely while not in use and that the necessary maintenance services are performed.

The asset manager should have access to a storage space to hold the unallocated assets, which can be anything from a locked cupboard to a storage room. The assets should be stored by category, with their asset tags or markings easy to read while in storage.

Some assets, such as buildings and vehicles, require insurance. Assets must be insured locally unless they are purchased in an organisation that holds global insurance for their assets (always ask your regional logistics coordinator to confirm the status of partners’ asset insurance).

Unless it is a legal or donor requirement, if the insurance cost is higher than the replacement cost (and if this can be shown through quotes), taking out an insurance policy is not mandatory.

Owned buildings, property or land must be captured on the asset register but rented properties may or may not have to be, depending on the duration and financial management of the lease (depreciation can sometimes be applied to long-term rental agreements). Refer to your finance team and/or to the UK-based logistics coordinators to confirm whether a leased building or property should be on the asset register.

Note: some donors may require some categories of assets to be insured. In this case, insurance costs should be covered by the donor requesting the insurance.

Asset checks

Asset checks should be conducted regularly. It is good practice to have five per cent of the asset register, or a minimum of ten assets (whichever is highest) checked against the asset register by finance and logistics staff in each of the country offices on a monthly basis, using the asset spot check form.

All differences must be investigated and reported on the asset spot check form by the staff who conducted the spot check (finance and logistics) and signed:

Locally: by the asset manager’s line manager, programme manager or country manager.

HQ level: by the head of logistics.

The asset spot check form must be signed within a month of being raised, asset checks are required by default, unless otherwise specified in the . The asset spot check form does not need HQ sign-off if it does not identify discrepancies.

A full physical check of all assets must be completed by finance and logistics staff on an annual basis, preferably just before the end of the financial year. All differences must be investigated and reviewed per the same process as for asset spot checks. Following the annual asset check, the asset register must be updated, and the approved investigation report must be attached to the next dissemination of the asset register.

All asset check forms must be kept in the asset management file. The asset manager must keep track of the assets that have been checked during the monthly spot checks to ensure that different assets are checked each month, on a rolling basis.

Following the monthly spot check, the asset register must be updated and the spot check form should be attached to the next dissemination of the asset register.

Reporting on assets

Most donors require regular information about assets purchased with funds they have provided. The details in the asset register should cover all the information they require, but it is good practice to agree beforehand on the information that will be shared.

Whenever new partnerships are designed, it is advisable that the future grant recipient shares their version of an asset register with the donor, to ensure that the level of information is sufficient.

Assets that have not been used for over a year should be reported to senior management by the asset manager, to discuss potentially disposing of them. See the Asset disposal section for more details.

Asset depreciation

The value of assets owned by an organisation sits on its balance sheet. Keeping the balance sheet updated is usually the responsibility of the finance team, but the information required for the process is often shared between logistics and finance. Communication between teams is critical when it comes to recording the right assets at the right value.

In the British Red Cross, see the “Guidance on accounting for fixed assets” (available on Redroom) for information about capitalising assets. Note that in , each team is responsible for their own assets and must maintain an asset register to be shared with the finance team when required (for the end-of-year report for example).

At British Red Cross, assets with a value above £1,000 and with a useful life of more than one year must be capitalised and depreciated. Further details can be found in the policy. Finance should be consulted to understand which assets incur depreciation (not all of them will).

An asset will typically be allocated a life cycle of x years, and its value will decrease by the same amount every year for x years. At the end of x-year life cycle, the asset’s value will be 0. Those 0-value assets still need to be managed as all other assets, and their status must be updated on the asset register.

It is not the responsibility of logistics to apply depreciation to the assets. The asset manager must make sure the depreciated values are computed and shared in due time to report on the total value of assets.

Asset maintenance

Assets that require regular maintenance or inspection services typically include:

- all fleet, including generators and mechanical handling devices (i.e. forklifts)

- buildings, whether owned or rented

- medical equipment

- IT and comms equipment

- some household items.

Regular maintenance

Regular maintenance should be incorporated into the usage cycle of assets. For example, it should be reflected in the fleet plan and the drivers’ allocation plan.

A maintenance planner should be used to visualise all completed, ongoing and upcoming maintenance, and covering all the assets that require maintenance. A maintenance planner is included as a tab in the asset register template. It is important to consider legal requirements that apply to categories of assets: for example, an annual vehicle inspection is required in certain countries, with the renewal of the roadworthiness certificate.

See the Fleet chapter for more details on fleet maintenance and maintenance planning.

See the British Red Cross portable appliances technical guide for details of the maintenance procedures to follow regarding British Red Cross-owned electrical assets in the UK. This guide should inform the maintenance planner for the UK logistics team.

See guideline for maintenance of British Red Cross-owned vehicles in the UK.

Note: Most of the maintenance requirements for buildings in the UK will be covered by British Red Cross’ maintenance service provider. To request a maintenance service, contact , so they can schedule it via the facilities management contractor.

Unplanned maintenance

Unplanned maintenance needs must be identified as such and avoided as far as possible. When they do occur, a maintenance request must be authorised by the asset manager, and the associated costs should be recharged to the budget code of the user requesting the maintenance.

Cost of maintenance

The cost of maintenance associated with an asset should be monitored, with copies of invoices for maintenance services included in the individual asset files kept in the asset management folder.

Looking at the cumulative value of maintenance costs associated to a specific asset can support a decision to dispose of an asset, replace it or to switch to renting rather than owning similar items.

For vehicles, generators and some electrical/medical equipment, maintenance should also be captured in the logbook.

Read the next section on Asset donations here.

Related resources

Download useful tools and templates here

Download the full section here.

Note: In the following sections, vehicles can be cars, trucks, planes, or ships. Where variations from the process occur, they are detailed at each step.

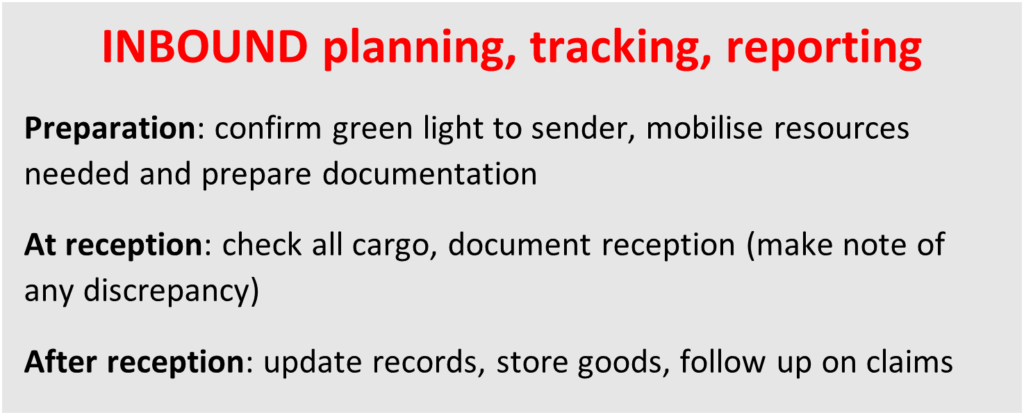

When planning inbound movements of freight (i.e. receiving a consignment):

Preparing for reception

The sender must always inform the consignee ahead of shipping goods, sharing as much information as possible on the shipment before the vehicles leave for delivery.

Information to share ahead of shipping:

- expected arrival date and time

- goods transported: a draft packing list or reference to orders (requisition), estimated weights and volumes

- vehicle details: registration, driver/pilot details and route. For sea shipments, this will be vessel route and shipping line

- special requirements: cold chain, dangerous goods, bulky equipment, etc.

- details of vehicles: schedule, number of trips and prioritisation.

The receiver should confirm their capacity to handle the inbound shipment and make necessary arrangements.

Arrange your reception area to ensure the full consignment can be temporarily stored before being moved into the bulk storage area – if necessary, make temporary adjustments to the warehouse layout to accommodate the incoming consignment.

Communicate temporary changes to the layout to the warehouse team.

To prepare for reception:

- plan for space to offload

- plan for documentation to track offloading process – ensure a detailed packing list is available

- plan for available manpower to offload

- plan for cold chain capacity if needed

- re-schedule planned orders with the warehouse team and end users

- prepare labels for storage

- rent or procure handling equipment if necessary

- prioritise processing order with end users.

Information to share after shipping:

- container seal number where relevant

- expected ETA

- copy of final transport document (waybill, bill of lading, air waybill, CMR where relevant)

- exact contents of consignment: final packing list, weights & dimensions, specific handling requirements and markings

- contact details of driver/pilot and rental company (if relevant).

The captain of a vessel can usually not be contacted directly, but vessels can be tracked by a bill of lading.

Note: where the shipper of the goods is the supplier of the same goods, the same details must be obtained from them.

| Sharing shipment details | Provided by | |

|---|---|---|

| Responsible | Shipper | Receiver |

| Accountable | Receiver | Receiver |

| Consulted | Receiver/requestor | Requestor |

| Informed | Requestor | Shipper |

At the time of reception

| When to count containers | When to count pallets | When to count boxes | When to count boxes' contents |

|

|---|---|---|---|---|

| Air | N/A | At airport if palletised | At airport if unpalletised At delivery place if palletised | At delivery place |

| Sea | At port | At port if possible At delivery place otherwise | At port if possible and unpalletised At delivery place if palletised | At delivery place |

| Road | At delivery place if relevant | At delivery place if relevant | At delivery place | At delivery place |

| Rail | At delivery place if relevant | At delivery place if relevant | At delivery place if relevant | At delivery place |

Available to download here.

Note: counting the contents of sea freight containers (pallets, boxes, loose goods, etc) can often not be done at the port and has to be done either at the final delivery place or at the freight forwarders/clearing agent’s premises.

Road consignments will usually be delivered straight to the delivery point. At the time of offloading, make sure every unit (pallet or box) is accounted for, and store them separately until the entire content of the boxes has been reviewed against the shipping documents accompanying the truck. Where a transhipment is needed, all pallets and boxes must be accounted for during the transhipment.

At time of reception:

- Check that all documents are attached to the consignment: commercial invoice, gift certificate, packing list, waybill, bill of lading, air waybill or CMR sheet (where applicable) and any customs clearance certificate (including tax waiver documents where applicable).

- Check that container seals are in good condition.

- Check the condition of each box/pallet as it is offloaded and check for labels.

- Confirm number of boxes matches the consignment documentation in each vehicle/container.

- Check and inspect the contents of each box to confirm exact quantities received against the packing list attached to the consignment.

Record any discrepancy and reconcile only once all boxes have been inspected (sometimes all ordered goods are in the consignment, but the packing lists are not accurately broken down per packaging unit). - If receiving a cold chain consignment, read the temperature-monitoring devices attached to the consignment, to confirm cold chain has been maintained throughout the transport process.

Offloading trucks

If available, use loading docks or platforms. Otherwise, position the truck on level, solid ground, as close as you can to where the goods must go to.

Allow enough space for movement around the truck, especially if you are using a forklift truck or hand pallet truck.

If you have inbound trucks and outbound trucks available simultaneously, consider whether it is worth trans-shipping directly from one truck to the other (as long as you can control the process and ensure accurate counting is done).

If handling equipment is not available, do not throw unidentified goods from a truck but hand them down carefully.

If goods must be manually handled because there is no handling equipment, use a chain of people (with one person in charge). The chain must have enough people for each person not to have to ‘walk’ more than one step. The people should be placed facing alternately along the chain to avoid unnecessary ‘twisting’.

View an example diagram of correct offloading of trucks here.

Avoid handling goods more times than you must by only putting them down where they have to go, in the stack they have to go in (see the Storage options section of Setting up a warehouse for more information on stacking). If the person you are handing the goods to is not ready, call the chain to stop.

Always maintain height if you can. Do not put goods on the floor if they must be lifted up again.

Make sure someone who is not handling the goods is counting as the goods are moved. That person should keep a tally (marking off per layer removed or built, for example), in case they get interrupted and cannot remember where they had counted to.

A check count should be done when each stack is created.

When all goods are offloaded, cross-check offloaded quantities against shipping documents and make note of any discrepancy.

Remember to take breaks when needed during offloading and make sure drinking water is readily available.

Documenting the reception

For details on how to receive goods in a warehouse, see the Receiving stock, Document the reception, Receiving stock for the British Red Cross (in UK or at Regional Logistics Units) and Releasing stock sections of the Warehousing chapter.

After reception of the goods

Record all received quantities on the appropriate stock cards and bin cards, referring to the GRN/ as appropriate.

Transfer the goods from the reception area to the main storage area as soon as possible.

In case of any claims, follow up on resolution options with the sender/transporter, agreeing on corrective measures to be put in place for future shipments where relevant.

Log the shipment in a shipment tracker, with complete details of the consignment – this will be used in the activity reporting process.

Inform the requestor and sender of completed delivery: share a copy of the GRN. Detail any measures being taken to address claims and raise (where applicable).

For more details on the reception of international cargo, refer to the Warehousing chapter.

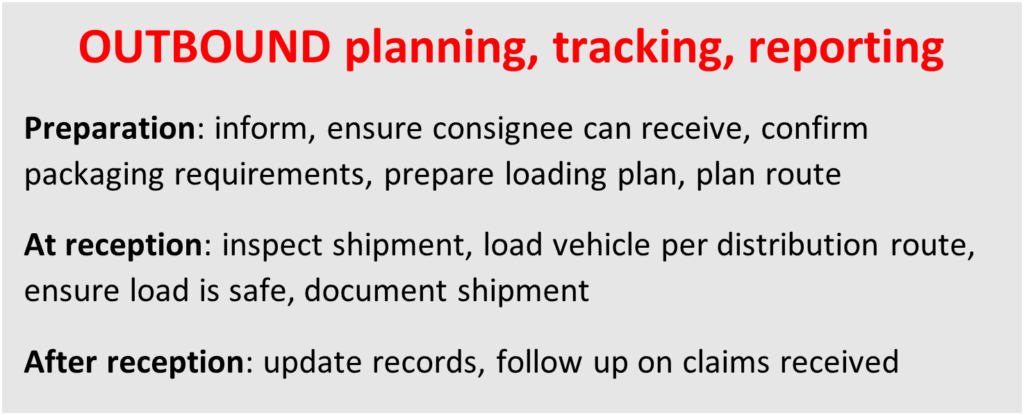

Preparing outbound shipments

When planning outbound movements of freight (i.e. shipping a consignment):

The sender must always inform consignee ahead of shipping goods, sharing as much information as possible on the shipment before the vehicles leave for delivery.

Information to share ahead of shipping:

- expected arrival date and time

- special requirements: cold chain, dangerous goods, bulky equipment, etc.

- goods transported: a draft packing list or reference to orders (requisition), estimated weights and volumes

- details of vehicles: schedule, number of trips and prioritisation

- vehicle details: registration, driver/pilot details and route. For sea shipments, this will be vessel route and shipping line.

Move the goods to be shipped to a designated dispatch area. The dispatch area can be temporarily modified as necessary, but make sure the warehouse team is informed of any changes.

Inspect the goods to be shipped: are all packaging units in good condition? Ensure cartons/pallets are stripped of any markings that could lead to confusion.

What are the packaging/labelling requirements? Be sure to ask the transporter and the consignee about any specific requirement they may have. Shipping instructions will also be helpful to find information about such requirements.

What will be the route of the vehicle, and the shipping mode? This will impact the loading plan and must be agreed with the transporter as early as possible. When sending sea shipments, control over the loading plan will be with the shipping line.

Where temperature control is required, cold chain materials (thermometer, temperature tracking devices, cool boxes, icepacks, etc.) must be made available.

Raise a final packing list with all details of the consignment. In the Red Cross movement, the waybill is often used as a packing list however it is sometimes easier to use both documents separately (for very large consignments for example).

Use a load optimisation tool to determine best transport options (this only works for road shipments).

Place the request for the necessary vehicles well in advance (as per the terms of the service-level agreement defined in the contract, where relevant), ensuring that you receive driver/pilot details and a vehicle registration certificate before the shipping date.

Ensure the necessary manpower and loading equipment will be available for loading the vehicles.

When using shipping containers, make sure the use of the containers is optimised and suggest changes in quantities where relevant (e.g., when five per cent of the order does not fit into a single container, the consignee might be willing to postpone the delivery to save the cost of the extra container).

Based on the number of packaging units shipped, prepare a loading sheet to give to the loaders, so they can track the progress of the loading process.

Where multiple vehicles are transporting multiple items, agree in advance the load composition (i.e. whether each vehicle holds a combination of all the items or only one type of item).

Loading trucks

- If available, use loading docks or platforms. Otherwise, position the truck on level, solid ground as close as you can to where the goods have to go to or come from.

- Allow enough space for movement around the truck, especially if you are using a forklift or hand pallet truck.

- If handling equipment is not available, do not throw unidentified goods from a truck but hand them down carefully.

- When loading trucks, always stack goods starting at the front of the truck and work towards the back.

- Always place the heaviest goods on the floor of the vehicle.

- Rules about stacking also apply on a truck (see the Storage options section of Setting up a warehouse).

- If you are loading a truck for distribution, lay the goods along the length of the vehicle, so that complete sets of whatever is being delivered can be distributed off the back of the truck (unless the truck has an open top or can be easily accessed from the sides, like a ‘wing’ truck).

View an example diagram of a truck loaded for direct distribution here.

At the time of dispatching

- Hand out loading sheets to loaders and retrieve them after the vehicle is loaded.

The loading sheet should simply list all the parcels to be loaded, and one loader should monitor loading progress by ticking the parcels off as they are loaded on the truck. - Confirm the route of the vehicle.

- Raise a waybill, detailing the quantity of units (pallets, sacks, boxes) loaded, weight and volume per unit and total weight and volume of the consignment.

Alternatively, waybills can detail the total quantity, weight and volume per item included in the consignment (in particular when goods are sent unpalletized or loose). - Place seals on containers where necessary.

- Ensure load is safe (with no risk of spillage or cross-contamination, etc) and securely fastened inside the vehicle – straps can be used, or blankets can be used to secure a load on a half-empty truck, for example.

- When sending a cold chain shipment, double check the cold chain plan and ensure that clear instructions are given to the transporter.

The shipper and the driver must sign the waybill and one copy must stay at the origin.

Documenting the consignment

- The transporter will leave with three copies of the waybill.

- Certain countries or regions will require the shipper to obtain a permit to access certain areas – make sure you request such permits from the relevant authorities.

- Keep a copy of the outbound waybill, to be reconciled with the returned signed copy after reception is confirmed by the receiver.

- Where delivery is planned directly at a usage point (a distribution point where no stocks are managed, for example), a GRN will have to be raised.

The delivery will not always happen at a warehouse, so a logistician should go to the delivery site and conduct the check of the delivered items and raise the GRN with the requestor of the goods.

Where goods are missing or damaged, the GRN will be returned with a filled-out claims form.

It is safer to ensure that drivers/pilots are issued with a mission order, confirming that they are moving humanitarian goods. A standard mission order should be available in each delegation/mission/project.

After dispatch

- Log the shipment in a shipment tracker, with details of the consignment. This will be used in the activity reporting process.

- Update your stock cards and bin cards (where relevant).

- Inform the receiver of revised expected time of arrival and confirm the transporter’s contact details.

- After receiving the returned signed copy of the waybill and GRN, where claims have been raised, make sure they are addressed, and that a corrective plan is in place to avoid future disruptions.

Read the next section on Shipping instructions here.

Related resources

Download useful tools and templates