Note: In the following sections, vehicles can be cars, trucks, planes, or ships. Where variations from the process occur, they are detailed at each step.

When planning inbound movements of freight (i.e. receiving a consignment):

Preparing for reception

The sender must always inform the consignee ahead of shipping goods, sharing as much information as possible on the shipment before the vehicles leave for delivery.

Information to share ahead of shipping:

- expected arrival date and time

- goods transported: a draft packing list or reference to orders (requisition), estimated weights and volumes

- vehicle details: registration, driver/pilot details and route. For sea shipments, this will be vessel route and shipping line

- special requirements: cold chain, dangerous goods, bulky equipment, etc.

- details of vehicles: schedule, number of trips and prioritisation.

The receiver should confirm their capacity to handle the inbound shipment and make necessary arrangements.

Arrange your reception area to ensure the full consignment can be temporarily stored before being moved into the bulk storage area – if necessary, make temporary adjustments to the warehouse layout to accommodate the incoming consignment.

Communicate temporary changes to the layout to the warehouse team.

To prepare for reception:

- plan for space to offload

- plan for documentation to track offloading process – ensure a detailed packing list is available

- plan for available manpower to offload

- plan for cold chain capacity if needed

- re-schedule planned orders with the warehouse team and end users

- prepare labels for storage

- rent or procure handling equipment if necessary

- prioritise processing order with end users.

Information to share after shipping:

- container seal number where relevant

- expected ETA

- copy of final transport document (waybill, bill of lading, air waybill, CMR where relevant)

- exact contents of consignment: final packing list, weights & dimensions, specific handling requirements and markings

- contact details of driver/pilot and rental company (if relevant).

The captain of a vessel can usually not be contacted directly, but vessels can be tracked by a bill of lading.

Note: where the shipper of the goods is the supplier of the same goods, the same details must be obtained from them.

| Sharing shipment details | Provided by | |

|---|---|---|

| Responsible | Shipper | Receiver |

| Accountable | Receiver | Receiver |

| Consulted | Receiver/requestor | Requestor |

| Informed | Requestor | Shipper |

At the time of reception

| When to count containers | When to count pallets | When to count boxes | When to count boxes' contents |

|

|---|---|---|---|---|

| Air | N/A | At airport if palletised | At airport if unpalletised At delivery place if palletised | At delivery place |

| Sea | At port | At port if possible At delivery place otherwise | At port if possible and unpalletised At delivery place if palletised | At delivery place |

| Road | At delivery place if relevant | At delivery place if relevant | At delivery place | At delivery place |

| Rail | At delivery place if relevant | At delivery place if relevant | At delivery place if relevant | At delivery place |

Available to download here.

Note: counting the contents of sea freight containers (pallets, boxes, loose goods, etc) can often not be done at the port and has to be done either at the final delivery place or at the freight forwarders/clearing agent’s premises.

Road consignments will usually be delivered straight to the delivery point. At the time of offloading, make sure every unit (pallet or box) is accounted for, and store them separately until the entire content of the boxes has been reviewed against the shipping documents accompanying the truck. Where a transhipment is needed, all pallets and boxes must be accounted for during the transhipment.

At time of reception:

- Check that all documents are attached to the consignment: commercial invoice, gift certificate, packing list, waybill, bill of lading, air waybill or CMR sheet (where applicable) and any customs clearance certificate (including tax waiver documents where applicable).

- Check that container seals are in good condition.

- Check the condition of each box/pallet as it is offloaded and check for labels.

- Confirm number of boxes matches the consignment documentation in each vehicle/container.

- Check and inspect the contents of each box to confirm exact quantities received against the packing list attached to the consignment.

Record any discrepancy and reconcile only once all boxes have been inspected (sometimes all ordered goods are in the consignment, but the packing lists are not accurately broken down per packaging unit). - If receiving a cold chain consignment, read the temperature-monitoring devices attached to the consignment, to confirm cold chain has been maintained throughout the transport process.

Offloading trucks

If available, use loading docks or platforms. Otherwise, position the truck on level, solid ground, as close as you can to where the goods must go to.

Allow enough space for movement around the truck, especially if you are using a forklift truck or hand pallet truck.

If you have inbound trucks and outbound trucks available simultaneously, consider whether it is worth trans-shipping directly from one truck to the other (as long as you can control the process and ensure accurate counting is done).

If handling equipment is not available, do not throw unidentified goods from a truck but hand them down carefully.

If goods must be manually handled because there is no handling equipment, use a chain of people (with one person in charge). The chain must have enough people for each person not to have to ‘walk’ more than one step. The people should be placed facing alternately along the chain to avoid unnecessary ‘twisting’.

View an example diagram of correct offloading of trucks here.

Avoid handling goods more times than you must by only putting them down where they have to go, in the stack they have to go in (see the Storage options section of Setting up a warehouse for more information on stacking). If the person you are handing the goods to is not ready, call the chain to stop.

Always maintain height if you can. Do not put goods on the floor if they must be lifted up again.

Make sure someone who is not handling the goods is counting as the goods are moved. That person should keep a tally (marking off per layer removed or built, for example), in case they get interrupted and cannot remember where they had counted to.

A check count should be done when each stack is created.

When all goods are offloaded, cross-check offloaded quantities against shipping documents and make note of any discrepancy.

Remember to take breaks when needed during offloading and make sure drinking water is readily available.

Documenting the reception

For details on how to receive goods in a warehouse, see the Receiving stock, Document the reception, Receiving stock for the British Red Cross (in UK or at Regional Logistics Units) and Releasing stock sections of the Warehousing chapter.

After reception of the goods

Record all received quantities on the appropriate stock cards and bin cards, referring to the GRN/ as appropriate.

Transfer the goods from the reception area to the main storage area as soon as possible.

In case of any claims, follow up on resolution options with the sender/transporter, agreeing on corrective measures to be put in place for future shipments where relevant.

Log the shipment in a shipment tracker, with complete details of the consignment – this will be used in the activity reporting process.

Inform the requestor and sender of completed delivery: share a copy of the GRN. Detail any measures being taken to address claims and raise (where applicable).

For more details on the reception of international cargo, refer to the Warehousing chapter.

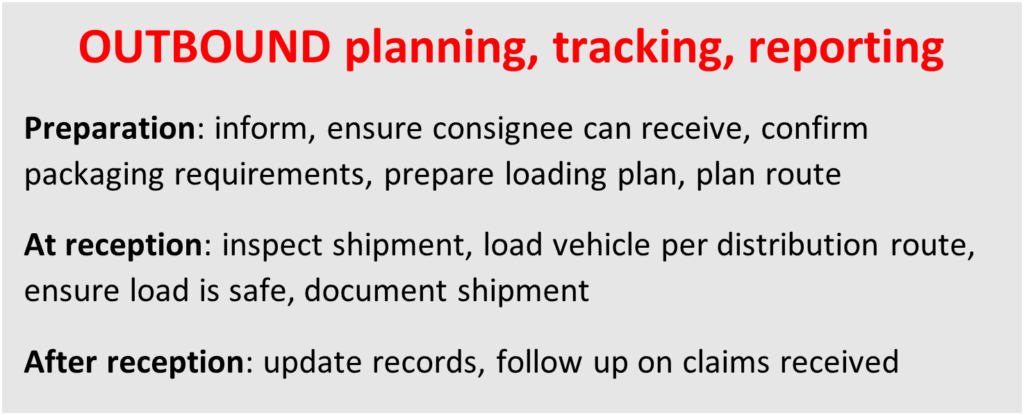

Preparing outbound shipments

When planning outbound movements of freight (i.e. shipping a consignment):

The sender must always inform consignee ahead of shipping goods, sharing as much information as possible on the shipment before the vehicles leave for delivery.

Information to share ahead of shipping:

- expected arrival date and time

- special requirements: cold chain, dangerous goods, bulky equipment, etc.

- goods transported: a draft packing list or reference to orders (requisition), estimated weights and volumes

- details of vehicles: schedule, number of trips and prioritisation

- vehicle details: registration, driver/pilot details and route. For sea shipments, this will be vessel route and shipping line.

Move the goods to be shipped to a designated dispatch area. The dispatch area can be temporarily modified as necessary, but make sure the warehouse team is informed of any changes.

Inspect the goods to be shipped: are all packaging units in good condition? Ensure cartons/pallets are stripped of any markings that could lead to confusion.

What are the packaging/labelling requirements? Be sure to ask the transporter and the consignee about any specific requirement they may have. Shipping instructions will also be helpful to find information about such requirements.

What will be the route of the vehicle, and the shipping mode? This will impact the loading plan and must be agreed with the transporter as early as possible. When sending sea shipments, control over the loading plan will be with the shipping line.

Where temperature control is required, cold chain materials (thermometer, temperature tracking devices, cool boxes, icepacks, etc.) must be made available.

Raise a final packing list with all details of the consignment. In the Red Cross movement, the waybill is often used as a packing list however it is sometimes easier to use both documents separately (for very large consignments for example).

Use a load optimisation tool to determine best transport options (this only works for road shipments).

Place the request for the necessary vehicles well in advance (as per the terms of the service-level agreement defined in the contract, where relevant), ensuring that you receive driver/pilot details and a vehicle registration certificate before the shipping date.

Ensure the necessary manpower and loading equipment will be available for loading the vehicles.

When using shipping containers, make sure the use of the containers is optimised and suggest changes in quantities where relevant (e.g., when five per cent of the order does not fit into a single container, the consignee might be willing to postpone the delivery to save the cost of the extra container).

Based on the number of packaging units shipped, prepare a loading sheet to give to the loaders, so they can track the progress of the loading process.

Where multiple vehicles are transporting multiple items, agree in advance the load composition (i.e. whether each vehicle holds a combination of all the items or only one type of item).

Loading trucks

- If available, use loading docks or platforms. Otherwise, position the truck on level, solid ground as close as you can to where the goods have to go to or come from.

- Allow enough space for movement around the truck, especially if you are using a forklift or hand pallet truck.

- If handling equipment is not available, do not throw unidentified goods from a truck but hand them down carefully.

- When loading trucks, always stack goods starting at the front of the truck and work towards the back.

- Always place the heaviest goods on the floor of the vehicle.

- Rules about stacking also apply on a truck (see the Storage options section of Setting up a warehouse).

- If you are loading a truck for distribution, lay the goods along the length of the vehicle, so that complete sets of whatever is being delivered can be distributed off the back of the truck (unless the truck has an open top or can be easily accessed from the sides, like a ‘wing’ truck).

View an example diagram of a truck loaded for direct distribution here.

At the time of dispatching

- Hand out loading sheets to loaders and retrieve them after the vehicle is loaded.

The loading sheet should simply list all the parcels to be loaded, and one loader should monitor loading progress by ticking the parcels off as they are loaded on the truck. - Confirm the route of the vehicle.

- Raise a waybill, detailing the quantity of units (pallets, sacks, boxes) loaded, weight and volume per unit and total weight and volume of the consignment.

Alternatively, waybills can detail the total quantity, weight and volume per item included in the consignment (in particular when goods are sent unpalletized or loose). - Place seals on containers where necessary.

- Ensure load is safe (with no risk of spillage or cross-contamination, etc) and securely fastened inside the vehicle – straps can be used, or blankets can be used to secure a load on a half-empty truck, for example.

- When sending a cold chain shipment, double check the cold chain plan and ensure that clear instructions are given to the transporter.

The shipper and the driver must sign the waybill and one copy must stay at the origin.

Documenting the consignment

- The transporter will leave with three copies of the waybill.

- Certain countries or regions will require the shipper to obtain a permit to access certain areas – make sure you request such permits from the relevant authorities.

- Keep a copy of the outbound waybill, to be reconciled with the returned signed copy after reception is confirmed by the receiver.

- Where delivery is planned directly at a usage point (a distribution point where no stocks are managed, for example), a GRN will have to be raised.

The delivery will not always happen at a warehouse, so a logistician should go to the delivery site and conduct the check of the delivered items and raise the GRN with the requestor of the goods.

Where goods are missing or damaged, the GRN will be returned with a filled-out claims form.

It is safer to ensure that drivers/pilots are issued with a mission order, confirming that they are moving humanitarian goods. A standard mission order should be available in each delegation/mission/project.

After dispatch

- Log the shipment in a shipment tracker, with details of the consignment. This will be used in the activity reporting process.

- Update your stock cards and bin cards (where relevant).

- Inform the receiver of revised expected time of arrival and confirm the transporter’s contact details.

- After receiving the returned signed copy of the waybill and GRN, where claims have been raised, make sure they are addressed, and that a corrective plan is in place to avoid future disruptions.

Read the next section on Shipping instructions here.

Related resources

Download useful tools and templates

Download full section here.

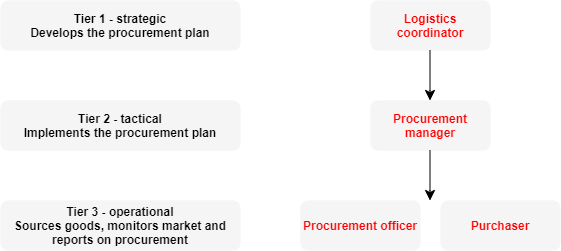

When working on a project, make sure the workload that procurement represents is clearly identified so it can be absorbed by your team. The standard roles involved in procurement are as below (see the IFRC logistics competency framework for reference):

Available to download here.

Standard job descriptions for procurement-focused positions can be requested from the international logistics team.

The logistics team’s structure should be defined in the early stages of the implementation phase, as per the process. Based on the project plan and other planning tools, such as the procurement plan and budget, a resource plan should be defined and implemented to support the programme’s activities.

At that stage, the programme team should define:

- the need for UK-based logistics support – some procurement processes will require support from the -based logistics team

- the need for in-country logistics support.

In terms of cost of procurement: the cost of items and services to be procured will often be budgeted while other costs related to procurement may be overlooked, such as delivery, administrative or handling costs. The identified procurement lead should make sure that these costs are budgeted for.

Read the next section on Procurement processes in the British Red Cross here.

Related resources

Download useful tools and templates

Download the full section here.

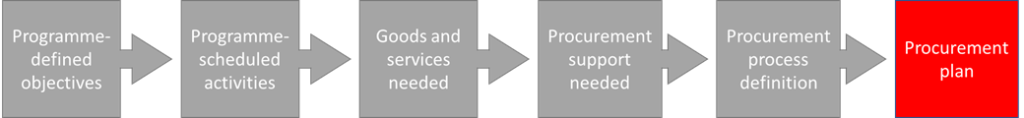

As part of the implementation phase* of the project, where the design phase* has helped identify needs that cannot be fulfilled with British Red Cross-owned resources (such as stock, staff, licenses or premises), the programme team and procurement lead will need to raise a procurement plan. This will capture sourcing options and manage the programme team’s expectations in terms of what should be available and when and enable the fulfilment of the activities that the programme has defined for itself.

The procurement plan is as much a work plan for the procurement team as a communications tool, and it will act as a service-level agreement between the procurement team/lead and the programme team/lead.

* These refer to the different stages identified in the British Red Cross International Quality Methodology (IQM) process. Details available from British Red Cross staff if required.

The procurement plan

How a procurement plan is designed

An indicator of likelihood of change should be included in the programme plan for each activity and objective.

Roles and responsibilities in developing a procurement plan

| Responsible | Procurement lead | Programme team |

| Accountable | Logistics department |

| Consulted | Finance | Warehouse | Technical adviser I UKO logs |

| Informed | Programme quality management | Programme team |

Available to download here.

Who can help develop a procurement plan?

- logistics

- for cash programmes: the Cash Hub

- experienced programme managers

- supply chain experts with local expertise

- finance staff (for cost indications)

- , , colleagues and other organisations.

What to consider when developing the procurement plan

How to obtain the goods

There are different methods to ensure that the material needed for the delivery of a programme are made available to the programme team.

- procurement – for high-value or high-risk items needed

- purchasing – for lower value, low-risk items needed

- donations – where reliable sources have resources beyond their needs

- loans – where items can be temporarily supplied by partners with subsequent replacements.

Waivers must be submitted to the head of logistics and approved on an individual basis, regardless of the value of the procurement. For procurement conducted in UKO, this is the role of the but UKO logistics can always advise and inform.

All waivers requested and obtained must be logged on the procurement plan. For UK-based procurement, a list of the waivers requested/obtained must be kept on a list of exceptions.

Where to obtain the goods from and where to deliver them

- local – small-scale retail, loan or donation system

- national – large suppliers who are part of a national supply network, national partners

- international – international supplier or donors, , and .

Note: the procurement plan also needs to define the exact delivery point for all the goods or services to procure.

Defining responsibilities

The below table displays an example of how the procurement process can be broken down into steps, matching each step with responsible, accountable, consulted and informed stakeholders.

This matrix should be completed, formally or informally, for each large procurement that is undertaken. There can be as many steps added to the matrix as necessary!

| Responsible | Accountable | Consulted | Informed | |

|---|---|---|---|---|

| Defining needs | ||||

| Raising requisition(s) | ||||

| Validating procurement process/route | ||||

| Procurement sign-off | ||||

| Contract negotiation | ||||

| Order management | ||||

| Quality check at delivery |

Available to download here.

When to conduct procurement

- Link to project timeline – match up procurement timeline to project objectives. Identify dependencies between activities.

- Procurement lead time – sourcing, contracting, manufacturing delivery – how long will it take?

- Reverse logistics plan – plan for any returns or exchanges which could be required.

Documents to support the procurement plan development

Reference documents for procurement plan development:

- project plan

- financial approvals matrix

- project budget

- specialist procurement guidelines*

- donor requirements*

- local procurement legal framework

- due diligence reports*

- audit reports*

- market assessment*

- HR matrix and organogram.

* Not always available or relevant

The scope of the required a market assessment (how deep and how wide does it need to be?) needs to be identified at the idea stage of the project (see British Red Cross guidance document) in alignment with both the available time and resources and the objectives defined for the project.

There are several tools available in the International Red Cross and Red Crescent Movement to support logisticians and programme teams in the market assessment and analysis process:

- Market analysis survey tool to capture average prices and availability of standard goods and services.

- Market assessments for cash-based interventions (such as or ) are key to understanding the functionality of markets, and its ability to support the objectives of the programme. They are available from the Cash Hub. The output of the market analysis will feed into the response options analysis and programme design and decision making.

For more details on market assessment and monitoring for cash programmes, refer to the Cash Hub and the logistics support to cash programmes matrix, from the Market Assessment and Analysis Principles paper.

Validating a procurement strategy

Based on the procurement plan and the estimated costs of items or services to be procured, it is helpful to identify the procurement lines that will consume the biggest share of the total cost at the design phase. This is useful for understanding where the efforts to conduct procurement should be focused.

A good rule of thumb to use is pareto analysis: calculate the total estimated spend on procurement, identify the 20 per cent highest-value procurement lines and invest 80 per cent.

There are other considerations to take into account, such as the urgency of the requirements. However, based on the pareto analysis, it will be critical to define and plan the procurement process of those lines which make up more than 80 per cent of the expected spend.

The pareto analysis can be based on expected amount to be spent, or on expected quantities to be procured. Typically, items that are purchased more than 50 per cent more often than others (and at regular intervals) should be purchased through long-term procurement agreements such as framework agreements.

In the UK, this is the role of the at – the UK logistics team act as an adviser or stakeholder in the procurement planning and strategy, driven by similar analyses. See the pareto step-by-step tool for more details on how to build your own pareto analysis into your procurement strategy.

The procurement strategy will flow from the procurement plan and from the pareto analysis and evolves based on the procurement reports that are available throughout the lifecycle of a project.

View and download a diagram of the procurement strategy flow here.

Read the next section on Planning resources for procurement here.

Related resources

Download useful tools and templates

Download the full section here.

Procurement

Definitions and concepts

The principles that drive procurement activities.

Learn more in the Definitions and concepts section.

Risk management

How to manage risk in procurement activities.

Learn more in the Risk management section.

When to procure

How to plan for effective procurement, monitor progress, evaluate and report on procurement.

Learn more in the Planning procurement section.

Why to procure

When required goods or services are unavailable to the organisation internally, they need to be sourced from third parties.

Learn more in the Sourcing for procurement section.

What to procure

How to select the best possible supplies to procure, delivering quality and value for money. How to procure items with special requirements.

Learn more in the Procurement of special items and services section.

How to procure

Procurement processes and procedures used at the British Red Cross and procurement resources within the Red Cross Movement, and how to use them.

Learn more in the Planning resources, Procurement processes, Sourcing and Managing procurement sections.

Who should procure

The stakeholders involved in procurement processes, roles and responsibilities.

Learn more in the Definitions and concepts and Planning resources for procurement sections.